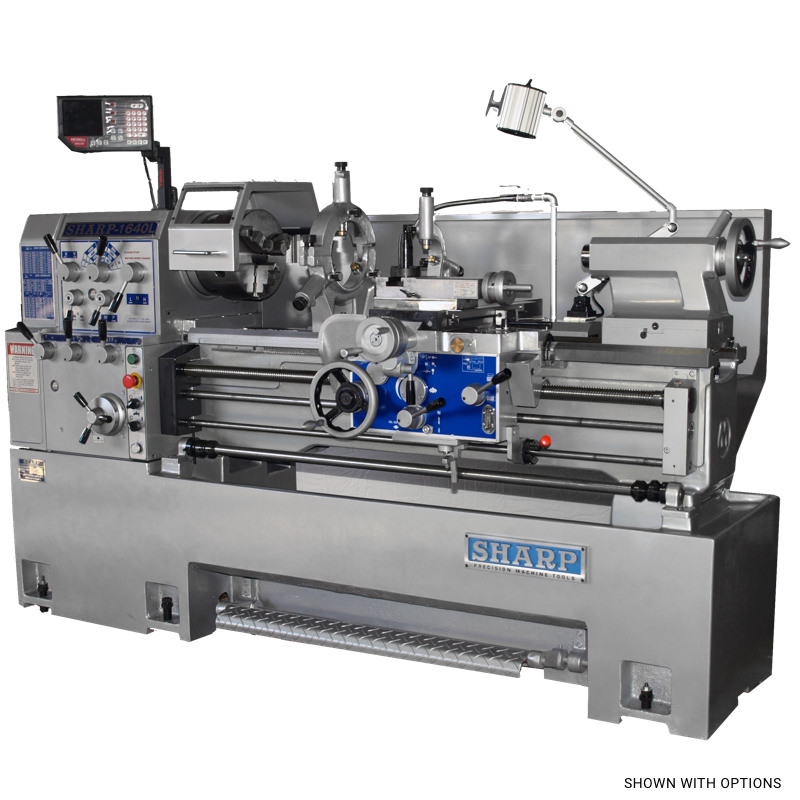

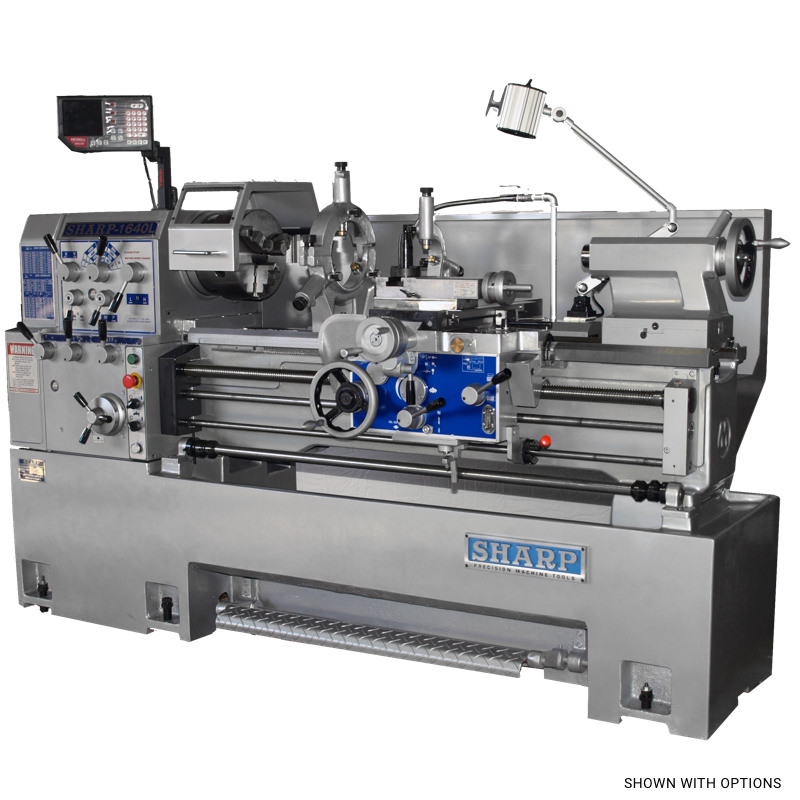

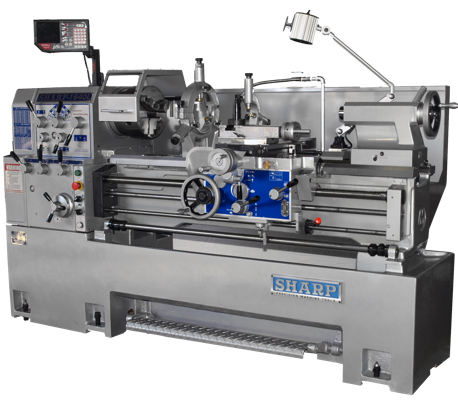

1880L

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

This model is designed with 3.18” spindle hole which is unique for 18” swing lathes. Due to its one piece casting machine base, it can support heavier cutting on large diameter materials. The large through hole allows most 3” diameter oil pipes to be machined.

3.18” spindle bore , largest spindle in this size lathes. More choices for different diameter of materials to be machined.

Capacity | Inch | Metric |

|---|---|---|

| Swing Over Bed | 18 in. | 457 mm |

| Swing Over Cross Slide | 10.2 in. | 259.08 mm |

| Swing Over Gap | 27.17 in. | 690 mm |

| Gap Width (In Front Of Face Plate) | 11.81 in. | 300 mm |

| Distance Between Centers | 86.6 in. | (2,200 mm) |

Headstock | Inch | Metric |

|---|---|---|

| Spindle Speed | 40-2,000 rpm | 40-2,000 rpm |

| Spindle Nose | D1-8 camlock | D1-8 camlock |

| Spindle Bore | 3.18 in. | 58 mm |

Threads and Feeds | Inch | Metric |

|---|---|---|

Threads, Number | 4-56 tpi, 36 | 0.5-7mm, 17 |

| Modular Threads, Number | 0.019-0.275 in., 17 | 0.5-7mm, 17 |

| Diametral Pitch Threads, Number | 0.157-2.20 in., 36 | 4-56 mm, 36 |

| Longitudinal Feeds | 0.002 - 0.032 in./rev | 0.05-0.82 mm/rev |

| Cross Feeds | 0.0001 –0.0094 in./rev | 0.02-0.4 mm/rev |

| Leadscrew Pitch, Diameter | 1.37 in., 35 mm | 1.37 in., 35 mm |

Carriage | Inch | Metric |

|---|---|---|

| Cross Slide Travel | 10.8 in. | 275 mm |

| Compound Travel | 4.92 in. | 125 mm |

| Compound Width | 5 in. | 127 mm |

Bed | Inch | Metric |

|---|---|---|

| Bed Length | 134 in. | 3,415 mm |

| Bed Width | 11.8 in. | 300 mm |

Tailstock | Inch | Metric |

|---|---|---|

| Quill Diameter | 2.68 in. | 68 mm |

| Quill Travel | 5.9 in. | 150 mm |

| Quill Center Taper | MT #4 | MT #4 |

General | Inch | Metric |

|---|---|---|

| Spindle Motor | 7.5 HP | 5.625 Kw |

| Voltage | 220V/440V | 230V/460V |

| Phase | 3 Phase | 3 Phase |

| Power Consumption (220 V) | 8KVA/25 amps | 8KVA/25 amps |

| Power Consumption (440 V) | 8KVA/12.5 amps | 8KVA/12.5 amps |

| Approximate Weight | 4,894.26 lbs. | 2,220 Kg |

| Dimensions | 11.22 x 2.66 x 4 ft. | 3.42 x 0.81 x 2.22 M |

All specifications subject to change without notice. Please call to verify.

| Swing x Center Dist. | 13 x 40 in. |

|---|---|

| Spindle Speed | 40 – 2,000 rpm vari. speed |

| Bore, HP | 1.6 in., D1-4, 3 hp |

| Swing x Center Dist. | 14 x 40 in. |

|---|---|

| Spindle Speed | 45 – 1,800 rpm (16) |

| Bore, HP | 1.5 in., D1-4, 3 hp |

| Swing x Center Dist. | 14 x 40 in. |

|---|---|

| Spindle Speed | 30 – 2,200 rpm vari speed |

| Bore, HP | 1.5 in., D1-4, 3 hp |

| Swing | 16 in. |

|---|---|

| Center Distance | 40 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 16 in. |

|---|---|

| Center Distance | 60 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 16 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

| Swing | 16 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.