RD-1600

| Column Diameter | 17 in. |

|---|---|

| Head Travel | 50 in. |

| Column to Spindle | 63 in. |

| Column Diameter | 17 in. |

|---|---|

| Head Travel | 50 in. |

| Column to Spindle | 63 in. |

This is a high performance machine ideal for drilling, tapping , boring, reaming, lapping, screwing, counter boring, spot facing, and much more, on materials such as cast iron and steel.

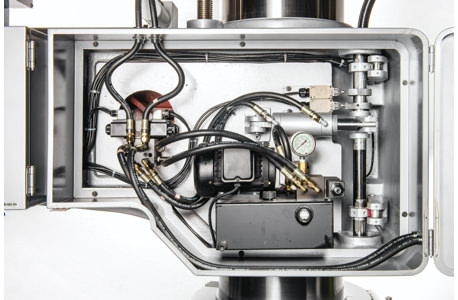

Individual power control (hydraulic) of arm, column and head clamping for easy positioning of spindle after change of tool

| Inch | Metric | |

|---|---|---|

| Diameter of column | 17 in. | 432 mm |

| Distance from column surface to spindle center, max. | 63 in. | 1600 mm |

| Distance from column surface to spindle center, min. | 13.37 in. | 339.59 mm |

| Travel of spindle head | 49.62 in. | 1260 mm |

| Distance from base surface to spindle end, max. | 63 in. | 1600 mm |

| Distance from base surface to spindle end, min. | 13 in. | 330 mm |

| Elevating height of arm | 35.43 in. | 900 mm |

| Effective area of table | 27.62 x 19.62 x 15.75 in. | 701.54 x 498.34 x 400 mm |

| Dimensions of base | 97.62 x 41.34 x 8.25 in. | 2479.54 mm |

| Taper hole in spindle | MT # 5 | MT # 5 |

| Stoke of spindle | 14.56 in. | 369.82 mm |

| R.P.M. of spindle (rpm range x steps) | 40-1920 x 12 steps | 40-1920 x 12 steps |

| Feed of spindle (1PR x steps) | 0.003-0.038 in. x 6 steps | 0.076-0.965 mm x 6 steps |

| Main motor (HP) | 7.5 HP | 5.59 Kw |

| Elevating motor (HP) | 2 HP | 1.49 Kw |

| Clamping motor for column and gear-box (HP) | 1 HP | 0.74 Kw |

| Clamping motor for arm (HP) | 1.5 HP | 1.11 Kw |

| Coolant pump (HP) | 1.12 HP | 0.83 Kw |

| Machine height from floor, max. | 10.40 ft. | 3.16 M |

| Measurement (LxWxH)/floor space | 8.5 x 3.75 x 8.75 ft. | 2.59 x 1.14 x 2.66 M |

| Measurement (LxWxH)/shipping dimensions | 9.16 x 4.75 x 9.58 ft. | 2.79 x 1.44 x 2.91 M |

| Shipping Weight | 10,340 lbs. | 4,690 Kg |

| Cast Iron | Inch | Metric |

|---|---|---|

| Drilling | 2.62 in. | 66.54 mm |

| Capacity Tapping | 2.37 in. | 60.19 mm |

| Boring | 7.37 in. | 187.19 mm |

| Steel | Inch | Metric |

|---|---|---|

| Drilling | 2.25 in. | 57.15 mm |

| Capacity Tapping | 2 in. | 50.8 mm |

| Boring | 5 in. | 127 mm |

| Total Power Consumptions | Inch | Metric |

|---|---|---|

| 220V | 12 KVA/35 amps | 12 KVA/35 amps |

| 440V | 12 KVA/17.5 amps | 12 KVA/17.5 amps |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.