1440V

| Swing x Center Dist. | 14 x 40 in. |

|---|---|

| Spindle Speed | 30 – 2,200 rpm vari speed |

| Bore, HP | 1.5 in., D1-4, 3 hp |

| Swing x Center Dist. | 14 x 40 in. |

|---|---|

| Spindle Speed | 30 – 2,200 rpm vari speed |

| Bore, HP | 1.5 in., D1-4, 3 hp |

The 14” swing precision lathe offer simple and easy operation for doing light work with all the features as a larger engine lathe. The economy value is ideal for schools, training for the next generation of skilled workers. It is also ideal for individual home machine shops. The electrics will accept single phase power supply.

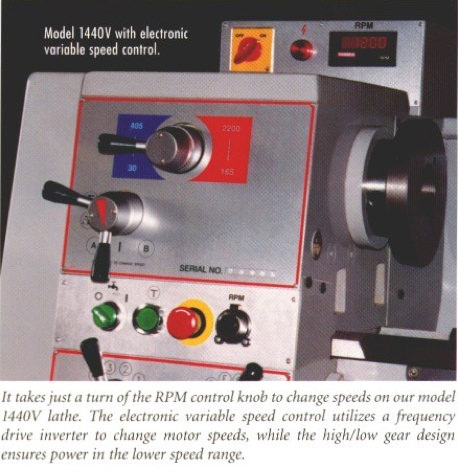

The variable speed headstock is designed with hi-low gear to offer better torque at the lower speed range. Change of the hi-low speed is done by shifting a lever. The rest of the speeds change are done by simply turning a knob. The headstock is equipped with jog button for engaging the gears before turning on the spindle to full speed.

This is a digital variable speed machine with Chrome-Moly material gears mounted on tapered roller bearings. The gears, bearings and shaft are lubricated by forced lubrication system. The top of the cross slide is hardened and ground for long term usage without scratching. The gap bed allows larger swing but short work piece to be machined near the headstock without changing to a larger swing machine. The tailstock is designed with the “tang” for easy knock off of centers.

Machine is available as a package with 2 axes digital readout system, chuck guard with limit switch, steady rest, follow rest and work light at a fixed price.

| Capacity | Inch | Metric |

|---|---|---|

| Swing Over Bed | 14 in. | 355.6 mm |

| Swing Over Cross Slide | 8.62 in. | 218.94 mm |

| Swing Over Gap | 20 in. | 508 mm |

| Gap Width (In Front Of Face Plate) | 9.25 in. | 234.9 mm |

| Distance Between Centers | 40 in. | 1,016 mm |

| Headstock | Inch | Metric |

|---|---|---|

| Spindle Speed | 30-2,200 rpm | |

| Spindle Nose | D1-4 camlock | |

| Spindle Bore | 1.5 in. | 38.1 mm |

Threads and Feeds | Inch | Metric |

|---|---|---|

Threads / Number | 4 - 112 tpi / 40 | 0.45 – 7.5 mm / 22 |

| Longitudinal Feeds | 0.0012 - 0.03 in./rev | 0.03 - 0.7 mm/rev |

| Cross Feeds | 0.0003 - 0.01 in./rev | 0.007 - 0.3 mm/rev |

| Leadscrew Pitch, Diameter | 8 tpi, 7/8 in. | 8 tpi, 22.225 mm |

| Carriage | Inch | Metric |

|---|---|---|

| Cross Slide Travel | 6.6 in. | 167 mm |

| Compound Travel | 4 in. | 101.6 mm |

| Compound Width | 3.5 in. | 88.9 mm |

| Bed | Inch | Metric |

|---|---|---|

| Bed Length | 66 in. | 1,676.4 mm |

| Bed Width | 8.5 in. | 206.24 mm |

| Tailstock | Inch | Metric |

|---|---|---|

| Quill Diameter | 1.75 in. | 44.45 mm |

| Quill Travel | 4.5 in. | 114.3 mm |

| Quill Center Taper | MT #3 |

| General | Inch | Metric |

|---|---|---|

| Voltage | 220V/440V | |

| Phase | 3 phase | |

| Power Consumption (220 V) | 3.2KVA/10 amps | |

| Power Consumption (440 V) | 3.2KVA/5 amps | |

| Approximate Weight | 1,650 lbs. | 748.42 Kg. |

| Dimensions | 6.29 x 2.41 x 3.91 ft. | 1.95 x 0.73 x 1.19 M |

All specifications subject to change without notice. Please call to verify.

| Swing x Center Dist. | 13 x 40 in. |

|---|---|

| Spindle Speed | 40 – 2,000 rpm vari. speed |

| Bore, HP | 1.6 in., D1-4, 3 hp |

| Swing x Center Dist. | 14 x 40 in. |

|---|---|

| Spindle Speed | 45 – 1,800 rpm (16) |

| Bore, HP | 1.5 in., D1-4, 3 hp |

| Swing | 16 in. |

|---|---|

| Center Distance | 40 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 16 in. |

|---|---|

| Center Distance | 60 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 40 – 2,000 rpm (12) |

| Swing | 16 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

| Swing | 16 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

| Swing | 18 in. |

|---|---|

| Center Distance | 40, 60 & 80 in. |

| Bore, HP | 3.1 in., D1-8, 7.5 hp |

| Spindle Speed | 20 – 2,000 rpm (2), vari. |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.