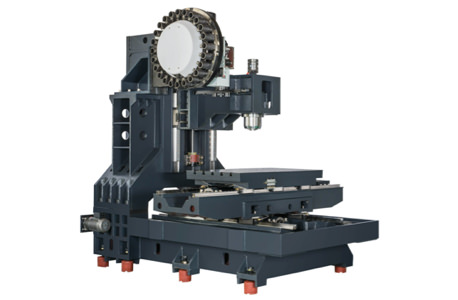

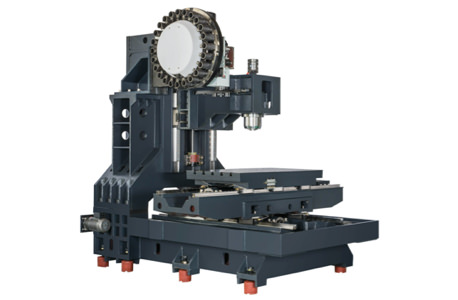

SVL-4023SX-F

| Travel | 40.16 x 23.62 x 23.62 in. |

|---|---|

| Taper, RPM | 40, 10k/12k |

| Tool Capacity | 24T/30T |

| Spindle Motor | 10/15 hp |

| Travel | 40.16 x 23.62 x 23.62 in. |

|---|---|

| Taper, RPM | 40, 10k/12k |

| Tool Capacity | 24T/30T |

| Spindle Motor | 10/15 hp |

This is a heavy duty machine that can perform extra heavy duty work. The elaborate design of the ribs in the castings offers superior rigidity than other machines of the same size.

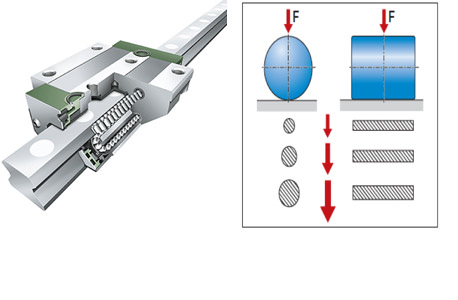

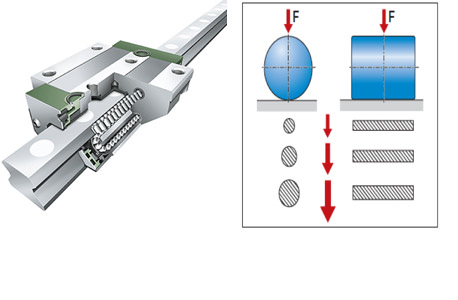

When subjected to a load, rollers form line contact with the guide surface, which is much larger than the point contact that is formed when balls are subjected to a load. This gives roller rail guides higher load capacities than ball rail guides of the same size.

Using Finite Element Analysis (FEA) the castings with the elaborate ribs design provides vibration dampening, thermal stability, torsional stiffness and optimum rigidity under different cutting conditions.

The spindle is designed with air curtain and air blast at tool change to prevent small chips from entering the inside of the quill. There are also directional coolant flush nozzle at the bottom part of the spindle for washing away chips. Around the spindle, there are coolant nozzles for cutting operation and air nozzle for cutting dry.

The control panel comes with 10” color screen and software such as high speed AICC, 200 blocks look ahead, rigid tapping, manual guide Oi, and extra M codes

The operating panel is equipped with detachable MPG (Manual Pulse Generator), USB port, RS-232, and embedded Ethernet

| Work Capacity | Inch | Metric |

|---|---|---|

| X axis travel | 41.3 in. | 1050 mm |

| Y axis travel | 23.6 in. | 600 mm |

| Z axis travel | 22 in. | 560 mm |

| Spindle nose to table | 5.9-28 in. | 150-710 mm |

| Spindle center to column | 24.4 in. | 620 mm |

| Worktable | Inch | Metric |

|---|---|---|

| Table area | 49.2 x 23.6 in. | 1250 x 600 mm |

| Max. workpiece weight | 1726 lbs. | 800 kg |

| T-Slot (Number x Width x Pitch) | 5 x 0.7 x 3.9 in. | 5 x 18 x 100 mm |

| Spindle | Inch | Metric |

|---|---|---|

| Spindle taper | Double contact CAT-40 | Double contact CAT-40 |

| Spindle speed | 12,000 rpm(12K) / 15,000 rpm(15K) | 12,000 rpm(12K) / 15,000 rpm(15K) |

| Spindle motor: cont./30 min | 10/15 HP | 7.5/11 kw |

| Transmission | Direct Drive | Direct Drive |

| Automatic Tool Changer | Inch | Metric |

|---|---|---|

| ATC type | Side Mount | Side Mount |

| Tool capacity | 30 | 30 |

| Max. tool diameter | 3.1 in. | 80 mm |

| Without adjacent tool | 5.9 in. | 150 mm |

| Max. tool length | 11.8 in. | 300 mm |

| Max. tool weight | 15.4 lbs. | 7 kg |

| Tool change time (tool to tool) | 1.3 sec | 1.3 sec |

| Method of tool selection | Random | Random |

| Motion | Inch | Metric |

|---|---|---|

| Rapid traverse | X/Y: 1417 ipm / Z: 1181 ipm | X/Y: 36,000 mm/min / Z: 30,000 mm/min |

| Cutting feed rate | 0.04-787 ipm | 1-20,000 mm/min |

| Transmission | Direct Drive | Direct Drive |

| Positioning accuracy* | 0.0002 in. within 300 mm range | 0.005 mm within 300 mm range |

| Repeatability accuracy* | 0.0001 in. | 0.003 mm |

| Linear guide width, X/Y/Z | 1.3 x 1.3 x 1.8 in. | 34 x 34 x 45 mm |

| Ball screw diameter, X/Y/Z | 1.41 x 1.41 x 1.57 in. | 36 x 36 x 40 mm |

| Coolant System | Inch | Metric |

|---|---|---|

| Coolant tank capacity | 53 gal | 200 L |

| Number of Coolant Nozzles | 4 | 4 |

| Machine Size | Inch | Metric |

|---|---|---|

| Floor space (w/o chip conveyor) | W: 130 in. x D: 106.6 in. | W: 3306 mm x D: 2710 mm |

| Height | 112 in. | 2840 mm |

| Weight | 12,122 lbs. | 5,510 kg |

| Operator door opening | 50.6 in. | 1285 mm |

| Power Requirements | Inch | Metric |

|---|---|---|

| Electrical | 220V/3 Phase / 20 KVA / 60Hz | 220V/3 Phase / 20 KVA / 60Hz |

| Air | 6 KG/cm2 | 6 KG/cm2 |

All specifications subject to change without notice. Please call to verify.

When subjected to a load, rollers form line contact with the guide surface, which is much larger than the point contact that is formed when balls are subjected to a load. This gives roller rail guides higher load capacities than ball rail guides of the same size.

Using Finite Element Analysis (FEA) the castings with the elaborate ribs design provides vibration dampening, thermal stability, torsional stiffness and optimum rigidity under different cutting conditions.

The spindle is designed with air curtain and air blast at tool change to prevent small chips from entering the inside of the quill. There are also directional coolant flush nozzle at the bottom part of the spindle for washing away chips. Around the spindle, there are coolant nozzles for cutting operation and air nozzle for cutting dry.

The control panel comes with 10” color screen and software such as high speed AICC, 200 blocks look ahead, rigid tapping, manual guide Oi, and extra M codes

The operating panel is equipped with detachable MPG (Manual Pulse Generator), USB port, RS-232, and embedded Ethernet

| Travel | 25.2 x 16.9 x 18.1, 25.2 x 16.9 x 23.6 in. |

|---|---|

| Taper, RPM | 40, 12k |

| Tool Capacity | 24 T |

| Spindle Motor | 10/15 hp |

| Travel | 45.3 x 25 x 20.1, 45.3 x 28 x 20.1 in. |

|---|---|

| Taper, RPM | 40, 15k |

| Tool Capacity | 30 T |

| Spindle Motor | 20/25 hp |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.