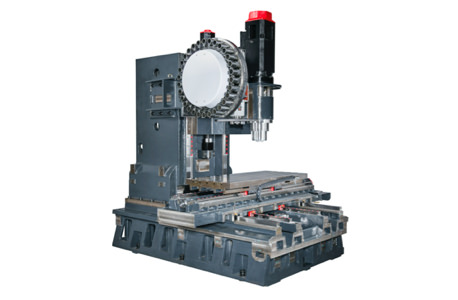

SVL-4500-Series

| Travel | 45.3 x 25 x 20.1, 45.3 x 28 x 20.1 in. |

|---|---|

| Taper, RPM | 40, 15k |

| Tool Capacity | 30 T |

| Spindle Motor | 20/25 hp |

| Travel | 45.3 x 25 x 20.1, 45.3 x 28 x 20.1 in. |

|---|---|

| Taper, RPM | 40, 15k |

| Tool Capacity | 30 T |

| Spindle Motor | 20/25 hp |

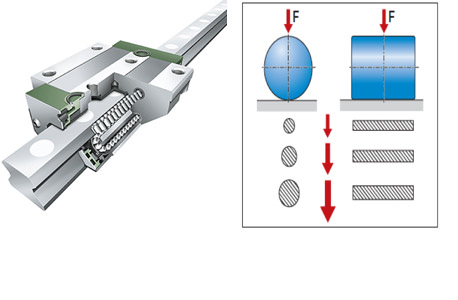

This is a massive, heavily ribbed castings machine with 2 linear roller pack ways on X/Y/Z axis and 2 additional box ways on Y axis. It is equipped with 3 axes linear scales for extra high precision works. It is designed specifically for heavy duty cutting with superior surface finish and is ideal for mold works. Machine weighs over 18,000 lbs.

Each axis is driven by a high precision double-nut ball screw that is centered between the guide ways.

The ball screws are pretensioned and anchored at both ends with angular contact bearings. Ball screws using single nuts or ones that are not pretensioned will have much greater play and backlash which can lead to problems with chatter and accuracy

The spindle is designed with air curtain and air blast at tool change to prevent small chips from entering the inside of the quill. Around the spindle, there are coolant nozzles for cutting operation and air nozzle for cutting dry.

| Work Capacity | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| X axis travel | 45.3 in. (1150 mm) | 45.3 in. (1150 mm) |

| Y axis travel | 25 in. (635 mm) | 28 in. (711 mm) |

| Z axis travel | 20.1 in. (510 mm) | 20.1 in. (510 mm) |

| Spindle nose to table | 5.1-25.2 in. (130-640 mm) | 5.1-25.2 in. (130-640 mm) |

| Spindle center to column | 31.5 in. (800 mm) | 31.5 in. (800 mm) |

| Worktable | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| Table area | 51.2 x 25 in. (1300 x 635 mm) | 51.2 x 25 in. (1300 x 635 mm) |

| Max. workpiece weight | 1760 lbs. (800 kg) | 1760 lbs. (800 kg) |

| T-Slot (Number x Width x Pitch) | 5 x 0.7 x 3.9 in. (5 x 18 x 100 mm) | 5 x 0.7 x 3.9 in. (5 x 18 x 100 mm) |

| Spindle | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| Spindle taper | CAT-40, Big plus | CAT-40, Big plus |

| Spindle speed | 15,000 (ceramic bearing) | 15,000 (ceramic bearing) |

| Spindle motor: cont./30 min | 20/25 hp (15/18.5 kw) | 20/25 hp (15/18.5 kw) |

| Transmission | Direct Drive | Direct Drive |

| Automatic Tool Changer | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| ATC type | Side Mount | Side Mount |

| Tool capacity | 30 | 30 |

| Max. tool diameter | 2.95 in. (75 mm) | 2.95 in. (75 mm) |

| Without adjacent tool | 5.9 in. (150 mm) | 5.9 in. (150 mm) |

| Max. tool length | 11.8 in. (300 mm) | 11.8 in. (300 mm) |

| Max. tool weight | 15.4 lbs. (7 kg) | 15.4 lbs. (7 kg) |

| Tool change time (tool to tool) | 2 sec | 2 sec |

| Tool change time (chip to chip) | 7 sec | 7 sec |

| Method of tool selection | Random | Random |

| Motion | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| Rapid traverse | X/Y/Z 1417 ipm (36,000 mm/min) | X/Y/Z 1417 ipm (36,000 mm/min) |

| Cutting feed rate | 0.04-1417 ipm (1-36,000 mm/min) | 0.04-1417 ipm (1-36,000 mm/min) |

| Transmission | Direct Drive | Direct Drive |

| Positioning accuracy* | 0.0002 in. (0.005 mm) | 0.0002 in. (0.005 mm) |

| Repeatability accuracy* | 0.00012 in. (0.003 mm) | 0.00012 in. (0.003 mm) |

| Ballscrew diameter X/Y/Z | 1.57 in. (40 mm) | 1.57 in. (40 mm) |

| Coolant System | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| Coolant tank capacity | 52.8 gal (200 L) | 52.8 gal (200 L) |

| Number of Coolant Nozzles | 4 | 4 |

| Machine Size | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| Floor space (w/o chip conveyor) | W: 171.5 in. (4356 mm) x 134.3 in. (3410 mm) | W: 171.5 in. (4356 mm) x 134.3 in. (3410 mm) |

| Height | 112 in. (3100 mm) | 112 in. (3100 mm) |

| Weight | 18,260 lbs. (8300 kg) | 18,260 lbs. (8300 kg) |

| Operator door opening | 45.3 in. (1150 mm) | 45.3 in. (1150 mm) |

| Power Requirements | SVL-4525SX-F | SVL-4528SX-F |

|---|---|---|

| Electrical | 220V / 3 Phase / 35 KVA / 60 Hz | 220V / 3 Phase / 35 KVA / 60 Hz |

| Air | 6 CFM at 88 psi | 6 CFM at 88 psi |

All specifications subject to change without notice. Please call to verify.

| Travel | 25.2 x 16.9 x 18.1, 25.2 x 16.9 x 23.6 in. |

|---|---|

| Taper, RPM | 40, 12k |

| Tool Capacity | 24 T |

| Spindle Motor | 10/15 hp |

| Travel | 40.16 x 23.62 x 23.62 in. |

|---|---|

| Taper, RPM | 40, 10k/12k |

| Tool Capacity | 24T/30T |

| Spindle Motor | 10/15 hp |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.