STC-Series

| Swing | 37 – 60 in. |

|---|---|

| Centers | 80 – 200 in. |

| Bore | 6, 9, 12 & 15 in. |

| Bed Width | 49 in. |

| Swing | 37 – 60 in. |

|---|---|

| Centers | 80 – 200 in. |

| Bore | 6, 9, 12 & 15 in. |

| Bed Width | 49 in. |

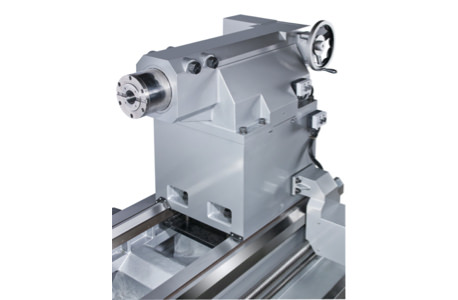

The extra heavy duty big bore spindle lathe offers spindle bores of 6”, 9”, 12”, 15”and 20” diameter for different sizes of materials. The center distance range from 60” to 315”. The machine bed is 49” wide. It is designed with 6 bedways. The cross slide and tailstock travels on separate bedways.

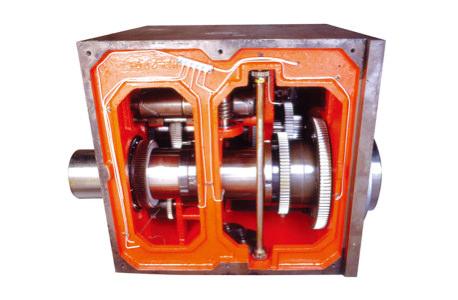

The headstock casting is designed with one ball bearing and two tapered roller bearings supporting the full length of the spindle shaft.

Spindle bore sizes are available in 6”, 9”’ 10″, 12” , and 15”. Double chucks are available as options.

Gears and shafts are made from hardened and ground alloy steel, the spindle is made from forged, chrome alloy material.

The oversized 24” wide bedways are induction hardened and ground for long lasting accuracy.

One piece casting bedways and base offer rigidity and stiffness to the entire machine to enhance heavy cutting

There are different types of optional turret tool posts to be mounted on the cross slide. There are 4 way, 6 way, 8, 12 positions hydraulic or motorized tool holding devices for different works.

The standard tailstock is equipped with a motorized quill feed and motorized tailstock base travel. Large hand crank allows convenient positioning of tailstock quill. Hydraulic tailstock lock along the bed is optional.

| Dimensions (STC-38200) | Inch | Metric |

|---|---|---|

| Maximum Swing Over Bed | 37.8 in. | 960 mm |

| Distance Between Centers | 196.9 in. | 5001 mm |

| Spindle Bore | 6 in. 9 in. 12 in. 15 in. | 152 mm 229 mm 305 mm 381 mm |

| Main Motor | 30 hp (Std.) 40 hp & 60 hp (Opt.) | 22.37 Kw 29.82 Kw & 44.74 Kw |

| CNC Control | FANUC Oi-TD | FANUC Oi-TD |

| Bed (STC-38200) | Inch | Metric |

|---|---|---|

| Bed Way Construction | 2 V, 2 Flat Ways | 2 V, 2 Flat Ways |

| Width of Bed | 49.2 in. | 1250 mm |

| Length of Bed | 272 in. | 6908 mm |

| Travel (STC-38200) | Inch | Metric |

|---|---|---|

| X-Axis Travel (Varies by different turrets installed) | 15.75 in. | 400 mm |

| Z-Axis Travel | 196.9 in. | 5001 mm |

| X-Axis Ball Screw Diameter | 1.57 in. | 40 mm |

| Z-Axis Ball Screw Diameter | 2.48 in. | 63 mm |

| Motor (STC-38200) | Inch | Metric |

|---|---|---|

| Spindle Motor | 30 hp (STD Fanuc Alpha 22) Opt: 40 hp or 60 hp | 22.37 Kw (STD Fanuc Alpha 22) Opt: 29.82 Kw & 44.74 Kw |

| X-Axis Servo Motor | 5 hp | 3.72 kw |

| Z-Axis Servo Motor | 5 hp | 3.72 kw |

| Hydraulic Pump | 2 hp | 1.5 kw |

| Coolant Pump | 1.7 hp | 1.27 kw |

| Machine Weight (STC-38200) | Inch | Metric |

|---|---|---|

| Weight | 47,300 lbs. | 21,455 kg |

| Dimensions (STC-38200) | Inch | Metric |

|---|---|---|

Length (Length with Chip Conveyor) | 31.58 ft. | 9.62 M |

| Width | 12.5 ft. | 3.81 M |

| Height | 7.41 ft. | 2.25 M |

Dimensions | STC-4480 | STC-44120 | STC-44160 | STC-44200 |

|---|---|---|---|---|

| Maximum Swing Over Bed | 44.09 in. (1120 mm) | 44.09 in. (1120 mm) | 44.09 in. (1120 mm) | 44.09 in. (1120 mm) |

| Distance Between Centers | 78.74 in. (2,000 mm) | 118.11 in. (3,000 mm) | 157.48 in. (4,000 mm) | 196.85 in. (5,000 mm) |

Maximum roll cutting dia. | 38.19 in. (970 mm) | 38.19 in. (970 mm) | 38.19 in. (970 mm) | 38.19 in. (970 mm) |

Minimum roll cutting dia. | 12.60 in. (320 mm) | 12.60 in. (320 mm) | 12.60 in. (320 mm) | 12.60 in. (320 mm) |

Maximum cutting length | 78.74 in. (2,000 mm) | 118.11 in. (3,000 mm) | 157.48 in. (4,000 mm) | 196.85 in. (5,000 mm) |

| Spindle Bore | 6 in. (152 mm) 9 in. (230 mm) 10 in (255 mm) 12 in. (305 mm) 15 in. (380 mm) | 6 in. (152 mm) 9 in. (230 mm) 10 in (255 mm) 12 in. (305 mm) 15 in. (380 mm) | 6 in. (152 mm) 9 in. (230 mm) 10 in (255 mm) 12 in. (305 mm) 15 in. (380 mm) | 6 in. (152 mm) 9 in. (230 mm) 10 in (255 mm) 12 in. (305 mm) 15 in. (380 mm) |

| Main Motor | 30 hp (Std.) 40 hp & 50 hp (Opt.) | 30 hp (Std.) 40 hp & 50 hp (Opt.) | 30 hp (Std.) 40 hp & 50 hp (Opt.) | 30 hp (Std.) 40 hp & 50 hp (Opt.) |

| CNC Control | FANUC Oi-TF | FANUC Oi-TF | FANUC Oi-TF | FANUC Oi-TF |

| Bed | STC-44120 | STC-44120 | STC-44160 | STC-44200 |

|---|---|---|---|---|

| Bed Way Construction | Multiple guides | Multiple guides | Multiple guides | Multiple guides |

| Width of Bed | 49.21 in. (1250 mm) | 49.21 in. (1250 mm) | 49.21 in. (1250 mm) | 49.21 in. (1250 mm) |

| Length of Bed | 157.48 in. (4000 mm) | 196.85 in. (5000 mm) | 236.22 in. (6000 mm) | 275.59 in. (7000 mm) |

| Travel | STC-4480 | STC-44120 | STC-44160 | STC-44200 |

|---|---|---|---|---|

| X-Axis Travel (Varies by different turrets installed) | 15.75 in. (400 mm) | 15.75 in. (400 mm) | 15.75 in. (400 mm) | 15.75 in. (400 mm) |

| Z-Axis Travel | 78.74 in. (2,000 mm) | 118.11 in. (3,000 mm) | 157.48 in. (4,000 mm) | 196.85 in. (5,000 mm) |

| X-Axis Ball Screw Diameter | 1.57 in. (40 mm) | 1.57 in. (40 mm) | 1.57 in. (40 mm) | 1.57 in. (40 mm) |

| Z-Axis Ball Screw Diameter | 2.48 in. (63 mm) | 2.48 in. (63 mm) | 2.48 in. (63 mm) | 2.48 in. (63 mm) |

| Motor | STC-4480 | STC-44120 | STC-44160 | STC-44200 |

|---|---|---|---|---|

| Spindle Motor | 30 hp (STD Fanuc Alpha 22) Opt: 40 hp or 50 hp | 30 hp (STD Fanuc Alpha 22) Opt: 40 hp or 50 hp | 30 hp (STD Fanuc Alpha 22) Opt: 40 hp or 50 hp | 30 hp (STD Fanuc Alpha 22) Opt: 40 hp or 50 hp |

| X-Axis Servo Motor | 5.3 hp (Fanuc AC servo) | 5.3 hp (Fanuc AC servo) | 5.3 hp (Fanuc AC servo) | 5.3 hp (Fanuc AC servo) |

| Z-Axis Servo Motor | 5.3 hp (Fanuc AC servo) | 5.3 hp (Fanuc AC servo) | 9.3 hp ( Fanuc AC servo) | 9.3 hp ( Fanuc AC servo) |

| Hydraulic Pump | 2 hp (1.5 kw) | 2 hp (1.5 kw) | 2 hp (1.5 kw) | 2 hp (1.5 kw) |

| Coolant Pump | 1.7 hp (1.27 Kw) | 1.7 hp (1.27 Kw) | 1.7 hp (1.27 Kw) | 1.7 hp (1.27 Kw) |

| Machine Weight | STC-4480 | STC-44120 | STC-44160 | STC-44200 |

|---|---|---|---|---|

| Weight | 35,200 lbs. (16,000 kg) | 39,600 lbs. (18,000 kg) | 44,100 lbs. 20,000 kg) | 48,500 lbs. (22,000 kg) |

| Dimensions | STC-4480 | STC-44120 | STC-44160 | STC-44200 |

|---|---|---|---|---|

Length (Length with Chip Conveyor) | 242.1 in. (6,150 mm) | 281.5 in. (7,150 mm) | 320.9 in. (8,150 mm) | 360.2 in. (9,150 mm) |

| Width | 150.4 in. (3,820 mm) | 150.4 in. (3,820 mm) | 150.4 in. (3,820 mm) | 150.4 in. (3,820 mm) |

| Height | 89.0 in. (2,260 mm) | 89.0 in. (2,260 mm) | 89.0 in. (2,260 mm) | 89.0 in. (2,260 mm) |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.