30-B-Series

| Swing | 30 in. |

|---|---|

| Center Distance | 60, 80, 100, 120, 160 in. |

| Bore, HP | 4.5 in., D1-11, 15 hp |

| Spindle Speed | 10 – 1,000 rpm (12) |

| Swing | 30 in. |

|---|---|

| Center Distance | 60, 80, 100, 120, 160 in. |

| Bore, HP | 4.5 in., D1-11, 15 hp |

| Spindle Speed | 10 – 1,000 rpm (12) |

This model has 4.5” spindle bore, D1-11 Camlock spindle nose, 16” wide bed, 15 HP motor offers great capacity for large work piece. The low speed goes down to 10 rpm offering enough torque for heavy cutting.

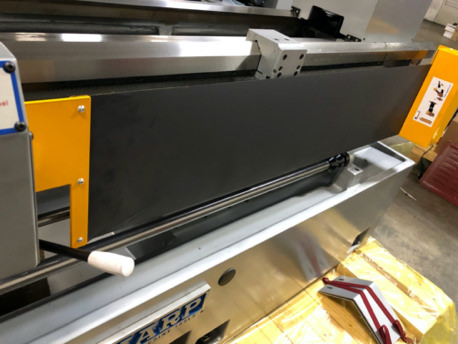

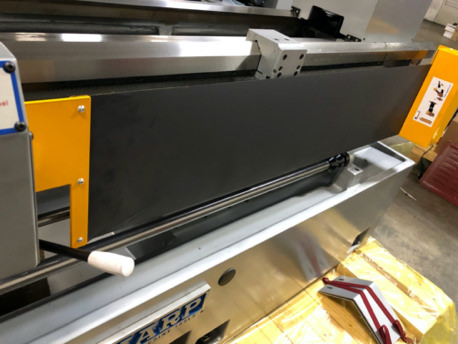

Optional leadscrew guard that covers entire front of bed

Example of large work piece handled by the B series lathe.

Capacity | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

| Swing Over Bed | 30 in. (760 mm) | 30 in. (760 mm) | 30 in. (760 mm) | 30 in. (760 mm) | 30 in. (760 mm) | 30 in. (760 mm) |

| Swing Over Cross Slide | 21-1/4" (540 mm) | 21-1/4" (540 mm) | 21-1/4" (540 mm) | 21-1/4" (540 mm) | 21-1/4" (540 mm) | 21-1/4" (540 mm) |

| Swing Over Gap | 39" (990 mm) | 39" (990 mm) | 39" (990 mm) | 39" (990 mm) | 39" (990 mm) | 39" (990 mm) |

| Distance Between Centers | 40" (1000 mm) | 60 in. (1,500 mm) | 80 in. (2,000 mm) | 100 in. (2,500 mm) | 120 in. (3,300 mm) | 160 in. (4,300 mm) |

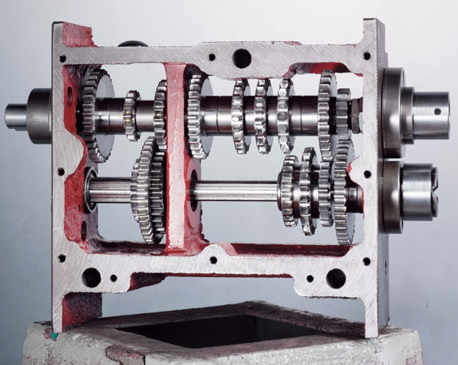

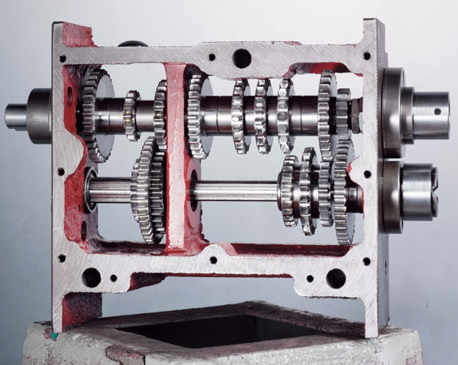

Headstock | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

Spindle Speed | 10-1,000 rpm | 10-1,000 rpm | 10-1,000 rpm | 10-1,000 rpm | 10-1,000 rpm | 10-1,000 rpm |

| No. of Spindle Speeds | 12 | 12 | 12 | 12 | 12 | 12 |

| Spindle Nose | D1 - 11 camlock | D1 -11 camlock | D1 -11 camlock | D1-11 camlock | D1-11 camlock | D1-11 camlock |

| Spindle Bore | 4.5 in. (120 mm) | 4.5 in. (120 mm) | 4.5 in. (120 mm) | 4.5 in. (120 mm) | 4.5 in. (120 mm) | 4.5 in. (120 mm) |

Threads and Feeds | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

Inch Threads Range | 2-56 TPI (D.P) | 2-56 TPI (D.P) | 2-56 TPI (D.P) | 2-56 TPI (D.P) | 2-56 TPI (D.P) | 2-56 TPI (D.P) |

Metric Threads Range | P0.5-14(M.P) | P0.5-14(M.P) | P0.5-14(M.P) | P0.5-14(M.P) | P0.5-14(M.P) | P0.5-14(M.P) |

| Longitudinal Feeds | 0.05-0.82 mm/rev | 0.05-0.82 mm/rev | 0.05-0.82 mm/rev | 0.05-0.82 mm/rev | 0.05-0.82 mm/rev | 0.05-0.82 mm/rev |

| Cross Feeds | 0.02-0.4 mm/rev | 0.02-0.4 mm/rev | 0.02-0.4 mm/rev | 0.02-0.4 mm/rev | 0.02-0.4 mm/rev | 0.02-0.4 mm/rev |

Leadscrew Pitch | 4 TPI or 6 mm | 4 TPI or 6 mm | 4 TPI or 6 mm | 4 TPI or 6 mm | 4 TPI or 6 mm | 4 TPI or 6 mm |

Leadscrew Diameter | 38 mm (1-1/2") | 38 mm (1-1/2") | 38 mm (1-1/2") | 38 mm (1-1/2") | 38 mm (1-1/2") | 38 mm (1-1/2") |

Carriage | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

| Cross Slide Travel | 17-3/4" (450mm) | 17-3/4" (450mm) | 17-3/4" (450mm) | 17-3/4" (450mm) | 17-3/4" (450mm) | 17-3/4" (450mm) |

| Compound Travel | 8" (200) | 8" (200) | 8" (200) | 8" (200) | 8" (200) | 8" (200) |

| Compound Width | 6 in. (150 mm) | 6 in. (150 mm) | 6 in. (150 mm) | 6 in. (150 mm) | 6 in. (150 mm) | 6 in. (150 mm) |

Bed | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

| Bed Length | 90.55 in. (2,300 mm) | 110.24 in. (2,800 mm) | 127.17 in. (3,230 mm) | 146.85 in. (3,730 mm) | 176.38 in. (4,480 mm) | 225.39 in. (5,725 mm) |

| Bed Width | 15.75 in. (400mm) | 15.75 in. (400mm) | 15.75 in. (400mm) | 15.75 in. (400mm) | 15.75 in. (400mm) | 15.75 in. (400mm) |

Tailstock | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

| Quill Diameter | 3-1/3" (85 mm) | 3-1/3" (85 mm) | 3-1/3" (85 mm) | 3-1/3" (85 mm) | 3-1/3" (85 mm) | 3-1/3" (85 mm) |

| Quill Travel | 7-1/2" (190 mm) | 7-1/2" (190 mm) | 7-1/2" (190 mm) | 7-1/2" (190 mm) | 7-1/2" (190 mm) | 7-1/2" (190 mm) |

| Quill Center Taper | MT #5 | MT #5 | MT #5 | MT #5 | MT #5 | MT #5 |

General | 3040B | 3060B | 3080B | 30100B | 30120B | 30160B |

|---|---|---|---|---|---|---|

| Spindle Motor | 15 HP (11 KW) | 15 HP (11 KW) | 15 HP (11 KW) | 15 HP (11 KW) | 15 HP (11 KW) | 15 HP (11 KW) |

| Voltage | 230V/460V | 230V/460V | 230V/460V | 230V/460V | 230V/460V | 230V/460V |

| Phase | 3 phase | 3 phase | 3 phase | 3 phase | 3 phase | 3 phase |

| Power Consumption (230V) | 6KVA/45 amps | 6KVA/45 amps | 16KVA/45 amps | 16KVA/45 amps | 16KVA/45 amps | 16KVA/45 amps |

| Power Consumption (460V) | 16KVA/22.5 amps | 16KVA/22.5 amps | 16KVA/22.5 amps | 16KVA/22.5 amps | 16KVA/22.5 amps | 16KVA/22.5 amps |

| Approximate Weight | 5,070 lbs. (2,300 kg) | 5,732 lbs. (2,600 kg) | 6,426lbs. (2,915 kg) | 7,275 lbs. (3,300 kg) | 7,981 lbs. (3,620 kg) | 9,039 lbs. (4,100 kg) |

| Dimensions | 8.23x5.07x4.53 ft (2.510x1.545x1.382) | 9.87x5.07x4.53 ft. (3.01x1.545x1.382 M) | 11.28x5.07x4.53 ft (3.94x1.545x1.382 M) | 12.92x5.07x4.53 ft. (3.94x1.545x1.382 M) | 22.76x5.07x4.53 ft. (4.69x1.545x1.382 M) | 18.78x5.07x4.53 ft. (5.725x1.545x1.92 M) |

Packing Dimensions (CM) | 270x115x193 cm | 355x106x168 cm | 361x115x193 cm | 410x115x193 cm | 485x115x196 cm | 588x115x196 cm |

All specifications subject to change without notice. Please call to verify.

Optional leadscrew guard that covers entire front of bed

Example of large work piece handled by the B series lathe.

| Swing | 22 in. |

|---|---|

| Center Distance | 40, 60, 80, 100, 120, 160 in. |

| Bore, HP | 4.5 in., D1-11, 15 hp |

| Spindle Speed | 10 – 1,000 rpm (12) |

| Swing | 26 in. |

|---|---|

| Center Distance | 40, 60, 80, 100, 120, 160 in. |

| Bore, HP | 4.5 in., D1-11, 15 hp |

| Spindle Speed | 10 – 1,000 rpm (12) |

| Swing | 24 in. |

|---|---|

| Center Distance | 80, 120 & 160 in. |

| Bore, HP | 4.125 in., D1-11, 15 hp |

| Spindle Speed | 10 – 1,200 rpm (18) |

| Swing | 30 in. |

|---|---|

| Center Distance | 80, 120 & 160 in. |

| Bore, HP | 4.125 in., D1-11, 15 hp |

| Spindle Speed | 10 – 1,200 rpm (18) |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.