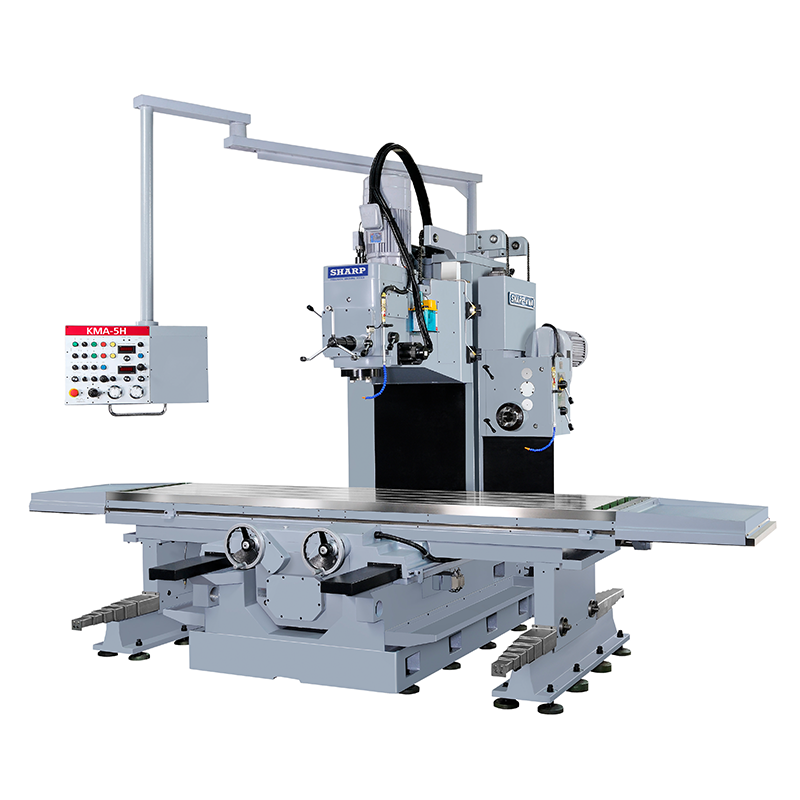

At Sharp Industries, we pride ourselves on designing high-performance machinery that meets the complex needs of modern manufacturing. This month, we are excited to shine the spotlight on our versatile KMA-5H bed type vertical/horizontal milling machine, which has proven to be an invaluable asset for companies across a wide range of industries. The KMA-5H seamlessly integrates both vertical and horizontal milling capabilities into one powerful machine, allowing manufacturers to handle even the most complicated machining tasks with precision and efficiency.

A Unique Design for Complex Operations

The KMA-5H is engineered to handle demanding projects that require high productivity and accuracy. With its 99” X 31.5” table travel, 50 taper spindle, and 17.5 HP geared head drive, it provides the versatility needed for complex operations. This dual capability, combining the strengths of both vertical and horizontal milling, allows businesses to optimize their processes and improve throughput without the need for multiple machines.

Whether you’re working on intricate parts for transportation infrastructure or bringing back outsourced work in-house, the KMA-5H delivers top-tier performance.

Over the past few weeks, we’ve seen a growing demand for the KMA-5H, with several companies across North America investing significantly in this cutting-edge technology. Here are a few examples of how the KMA-5H is transforming operations for manufacturers:

- NY/NJ Port Authority (Transportation Infrastructure)

The Port Authority recently acquired the KMA-5H to machine large, complete parts necessary for the ongoing maintenance of the Lincoln Tunnel. With its large table travel and robust spindle, the KMA-5H ensures that the Port Authority can complete their projects with unparalleled precision, keeping one of New York City’s most vital transportation links in optimal condition. - Ingredion (Food Processing in Kansas City)

Ingredion, a large food processing company based in Kansas City, invested in the KMA-5H to bring large work that was previously outsourced back in-house. The ability to handle large parts with ease has allowed Ingredion to increase operational efficiency, reduce lead times, and maintain high-quality production standards. - Turn-All Machine & Gear (Veteran-Owned Manufacturing in Ohio)

Turn-All Machine & Gear, a veteran-owned and operated machine and gear job shop in Ohio, purchased the KMA-5H to support their growing demand for heavy part machining in 2-axis. With the its versatility and reliability, Turn-All can now tackle complex parts with more control and reduce dependency on external suppliers.

The Perfect Solution for Heavy-Duty Machining Needs

With its robust design and features, the KMA-5H has quickly become the go-to solution for companies seeking to improve machining efficiency and precision. From infrastructure maintenance to food processing and heavy part manufacturing, Sharp’s KMA-5H is proving to be a game-changer for businesses that require the very best in productivity and performance.

If your company is looking for a milling machine that can handle complex operations while delivering superior precision and efficiency, reach out to Sharp Industries today to learn more about how our KMA Series can elevate your manufacturing capabilities.