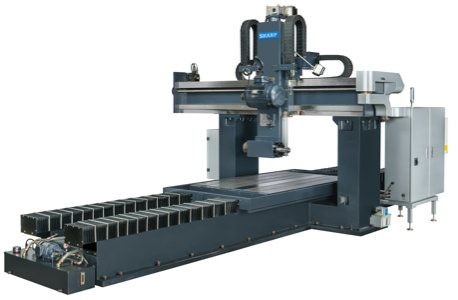

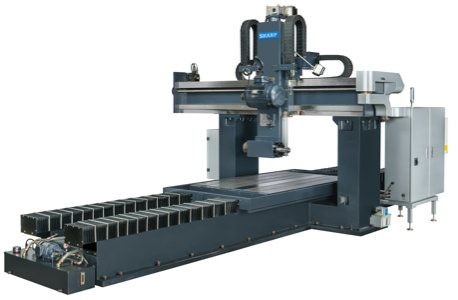

SHDC-60-SERIES

| Table Size | 47 x 240 in. |

|---|---|

| Spindle to Table | 43 in. |

| Column Clearance | 78 in. |

| Spindle HP | 15 hp |

| Table Size | 47 x 240 in. |

|---|---|

| Spindle to Table | 43 in. |

| Column Clearance | 78 in. |

| Spindle HP | 15 hp |

For extra large and heavy work piece the double column surface grinder is ideal for large plate, die mold, and ceramic plates. The different models available can grind workpieces of up to 20 ft (6,000 mm) long and 5 ft (1,500 mm) wide with high accuracy.

All major castings, the base, columns and cross beams are twice annealed to maintain high accuracy during machining. This process relieves internal stress that builds up during casting process. It also provides vibration dampening , low rate of thermal expansion and superior wear resistant characteristics.

The hydraulic table has two single action cylinders and piston rods to ensure smooth and steady travel of large work piece. Specially designed directional valve eliminates table reversal shock during fast movement of the large table.

Screen input allows automatic down feed of grinding wheel to the work piece in different sequences.

Input settings include:

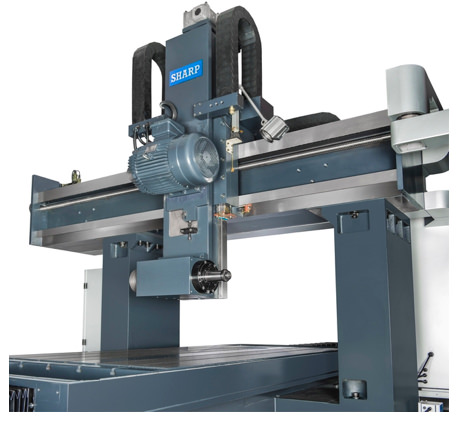

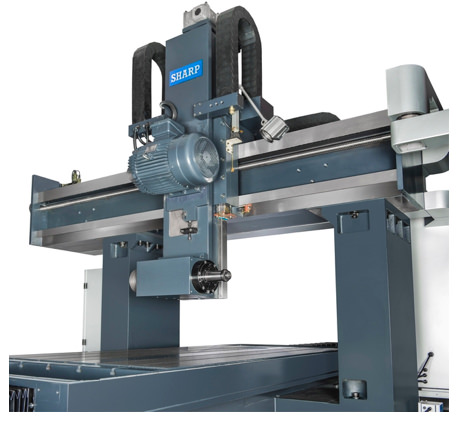

Grinding head travels on ball screw along cross beam. It is supported at two levels by flat and dovetail fully gibed ways. It provides secured and precise cross movements controlled on the operating panel. Micro adjustment of the cross travel is done by a large handwheel. Cross travel is available with servo drive on linear ways as an option.

Vertical down feed travels on wo box ways driven by servo motor operated by MPG. It also has rapid traverse for quick positioning driven by AC motor.

The long work table travels on hardened and ground double V ways that are precision hand scraped and TURCITE coated for long lasting wear and great stability. The extra long base fully support the travelling table to avoid table overhang.

| Capacity | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Table Travel | 74.8 X 92.5 in. (1,900 x 2,350 mm) | 74.8 X 124 in. (1,900 x 3,150 mm) | 74.8 x 163.4 (1,900 x 4,150 mm) | 74.8 x 202.8 in. (1,900 x 5,150 mm) | 74.8 x 242.1 in. (1,900 x 6,150 mm) |

| Spindle Center to Table Surface | 43.3 in. (1,100 mm) | 43.3 in. (1,100 mm) | 43.3 in. (1,100 mm) | 43.3 in. (1,100 mm) | 43.3 in. (1,100 mm) |

| Clearance Between Columns | 78.7 in. (2,000 mm) | 78.7 in. (2,000 mm) | 78.7 in. (2,000 mm) | 78.7 in. (2,000 mm) | 78.7 in. (2,000 mm) |

| Max Loading on the table | 10,600 lbs. (4,808 kg) | 10,600 lbs. (4,808 kg) | 10,600 lbs. (4,808 kg) | 10,600 lbs. (4,808 kg) | 10,600 lbs. (4,808 kg) |

| Table | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Working Surface | 59 x 92.5 in (1,500 x 2,200 mm) | 59 x 118.1 in. (1,500 x 3,000 mm) | 59 x 157.5 in. (1,500 x 4,000 mm) | 59 x 196.8 in. (1,500 x 5,000 mm) | 59 x 236.28 in. (1,500 x 6,000 mm) |

| Longitudinal Hydraulic Table Feed | 78.7-984 ipm (1-25 M) | 78.7-984 ipm (1-25 M) | 78.7-984 ipm (1-25 M) | 78.7-984 ipm (1-25 M) | 78.7-984 ipm (1-25 M) |

| Feed | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Intermittent Cross Feed | 0.004-1.38 in. (0.1-35 mm) | 0.004-1.38 in. (0.1-35 mm) | 0.004-1.38 in. (0.1-35 mm) | 0.004-1.38 in. (0.1-35 mm) | 0.004-1.38 in. (0.1-35 mm) |

| Continues Cross Feed | 118 ipm (3,000 mm/min) | 118 ipm (3,000 mm/min) | 118 ipm (3,000 mm/min) | 118 ipm (3,000 mm/min) | 118 ipm (3,000 mm/min) |

| Number of graduations on dial | 200 | 200 | 200 | 200 | 200 |

| Feed per division | 0.002 in. (0.05 mm) | 0.002 in. (0.05 mm) | 0.002 in. (0.05 mm) | 0.002 in. (0.05 mm) | 0.002 in. (0.05 mm) |

| Feed per Revolution | 0.39 in. (10 mm) | 0.39 in. (10 mm) | 0.39 in. (10 mm) | 0.39 in. (10 mm) | 0.39 in. (10 mm) |

| Vertical Travel | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Feed per Division | 0.00004 in. (0.001 mm) | 0.00004 in. (0.001 mm) | 0.00004 in. (0.001 mm) | 0.00004 in. (0.001 mm) | 0.00004 in. (0.001 mm) |

| Feed per Revolution | 0.01 in. (0.25 mm) | 0.01 in. (0.25 mm) | 0.01 in. (0.25 mm) | 0.01 in. (0.25 mm) | 0.01 in. (0.25 mm) |

| Rapid Traverse | 9.8 ipm (250 mm/min) | 9.8 ipm (250 mm/min) | 9.8 ipm (250 mm/min) | 9.8 ipm (250 mm/min) | 9.8 ipm (250 mm/min) |

| Grinding Wheel | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Wheel Size (OD x Width x ID) | 20 x 3.94 x 8 in. (510 x 100 x 203 mm) | 20 x 3.94 x 8 in. (510 x 100 x 203 mm) | 20 x 3.94 x 8 in. (510 x 100 x 203 mm) | 20 x 3.94 x 8 in. (510 x 100 x 203 mm) | 20 x 3.94 x 8 in. (510 x 100 x 203 mm) |

| Motor | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Horizontal Spindle Motor | 15 HP (11 Kw) | 15 HP (11 Kw) | 15 HP (11 Kw) | 15 HP (11 Kw) | 15 HP (11 Kw) |

| Hydraulic Motor (longitudinal) | 17.5 HP (13 Kw) | 17.5 HP (13 Kw) | 20 HP (14.91 Kw) | 20 HP (14.91 Kw) | 20 HP (14.91 Kw) |

| Spindle Speed | 1,150 rpm | 1,150 rpm | 1,150 rpm | 1,150 rpm | 1,150 rpm |

| General | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| Approximate Weight | 74,800 lbs. (34,000 kg) | 85,800 lbs. (39,000 kg) | 110,000 lbs. (50,000 kg) | 99,000 lbs. (45,000 kg) | 123,200 lbs. (56,000 kg) |

| Machine Dimensions | 21.66 x 11.5 x 12.5 ft. (6.6 x 3.5 x 3.8 M) | 27.58 x 11.5 x 12.5 ft. (8.4 x 3.5 x 3.8 M) | 36.75 x 11.5 x 12.5 ft. (11.2 x 3.5 x 3.8 M) | 44 x 11.5 x 12.5 ft. (13.4 x 3.5 x 3.8 M) | 51.16 x 11.5 x 12.5 ft. (15.6 x 3.5 x 3.8 M) |

| Total Power Consumptions | SHDC-6087 | SHDC-60120 | SHDC-60160 | SHDC-60200 | SHDC-60240 |

|---|---|---|---|---|---|

| 220V | 75 KVA | 75 KVA | 75 KVA | 75 KVA | 75 KVA |

All specifications subject to change without notice. Please call to verify.

All major castings, the base, columns and cross beams are twice annealed to maintain high accuracy during machining. This process relieves internal stress that builds up during casting process. It also provides vibration dampening , low rate of thermal expansion and superior wear resistant characteristics.

The hydraulic table has two single action cylinders and piston rods to ensure smooth and steady travel of large work piece. Specially designed directional valve eliminates table reversal shock during fast movement of the large table.

Screen input allows automatic down feed of grinding wheel to the work piece in different sequences.

Input settings include:

Grinding head travels on ball screw along cross beam. It is supported at two levels by flat and dovetail fully gibed ways. It provides secured and precise cross movements controlled on the operating panel. Micro adjustment of the cross travel is done by a large handwheel. Cross travel is available with servo drive on linear ways as an option.

Vertical down feed travels on wo box ways driven by servo motor operated by MPG. It also has rapid traverse for quick positioning driven by AC motor.

The long work table travels on hardened and ground double V ways that are precision hand scraped and TURCITE coated for long lasting wear and great stability. The extra long base fully support the travelling table to avoid table overhang.

| Table Size | 40 x 65 – 40 x 242 in. |

|---|---|

| Spindle to Table | 43 in. |

| Column Clearance | 47 in. |

| Spindle HP | 15 hp |

| Table Size | 47 x 80 – 47 x 240 in. |

|---|---|

| Spindle to Table | 43 in. |

| Column Clearance | 55 in. |

| Spindle HP | 15 hp |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.