SDC-205

| Travel | 204.7 x 141.7 x 39.3 in. |

|---|---|

| Table | 196.85 x 114.2 in. |

| Taper, RPM | CAT 50 |

| Tool Capacity | 30 T, 32 T |

| Spindle Motor | 30 & 35 hp |

| Travel | 204.7 x 141.7 x 39.3 in. |

|---|---|

| Table | 196.85 x 114.2 in. |

| Taper, RPM | CAT 50 |

| Tool Capacity | 30 T, 32 T |

| Spindle Motor | 30 & 35 hp |

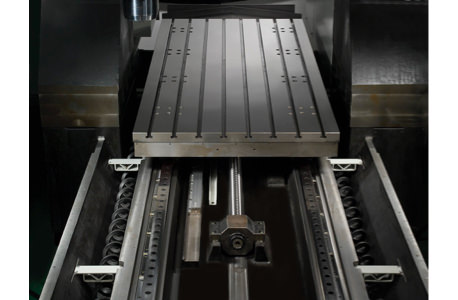

This is a Double Column Vertical Machining Center for large and heavy work piece. It is designed with Liner Roller Pack Ways for fast rapid traverse but still support heavy cutting condition.

TABLE | SDC-205 | SDC-205 |

|---|---|---|

Table size | 196.85" x 114.2" | 5000 x 2900 mm |

T slot width/number | 0.86"/ 7 | 22 mm/ 7 |

Maximum load | 44,000 lbs | 20,000KG |

TRAVEL | SDC-205 | SDC-205 |

|---|---|---|

Table travel (X axis) | 204.7" | 5200 mm |

Cross travel (Y axis) | 141.7" | 3600 mm |

Head vertical travel (Z-axis) | 39.3" | 1000 mm |

SPINDLE | SDC-205 | SDC-205 |

|---|---|---|

Motor (cont./30 min) | 30/35 HP | 22/26 Kw |

Speed | 6,000 rpm | 6,000 rpm |

Taper | CAT 50 | CAT 50 |

Separate milling heads | not available | not available |

DISTANCE | SDC-205 | SDC-205 |

|---|---|---|

Between two columns | 125" | 3200 mm |

Spindle nose to table surface | 7.8 - 47.2" | 200 - 1200 mm |

FEED RATE | SDC-205 | SDC-205 |

|---|---|---|

Rapid feed rate X/Y/Z | 394/472/394 in/min | 10/12/10 M/min |

Minimum setting | 0.00004 in/min | 0.001 mm/min |

Cutting feed rate | 196.8 in/min | 5 M/min |

ATC | SDC-205 | SDC-205 |

|---|---|---|

Tool change capacity | 24 | 24 |

Tool selection method | random | random |

Tool holder style | CAT 50 | CAT 50 |

Max tool dia (w,w/o tool) | 5/7.8" | 125/200 mm |

Max too weight | 39.6 lbs | 18 kg |

Max tool length w/0 adjacent | 9.8" | 250 mm |

Max tool length | 4.9" | 125 mm |

Tool to tool change time | 8 sec | 8 sec |

CNC | SDC-205 | SDC-205 |

|---|---|---|

Controller | FANUC Oi-MF Plus | FANUC Oi-MF Plus |

Memory length | 512KB | 1280 M |

USB memory interface | Yes | Yes |

POSITIONING ACCURACY | SDC-205 | SDC-205 |

|---|---|---|

X, Y axis | 0.0012 in | 0.032 mm |

Z axis | 0.0009 in | 0.025 mm |

REPEATIBILITY | SDC-205 | SDC-205 |

|---|---|---|

X, Y axis | 0.0005 in | 0.013 mm |

Z axis | 0.0004 in | 0.010 mm |

MISCEL | SDC-205 | SDC-205 |

|---|---|---|

Coolant tank capacity | 184 G | 700 L |

Hydraulic tank capacity | 21 G | 80 L |

Lubrication tank capacity | 2 G | 8 L |

Power requirement | 50 KVA | 50 KVA |

Air pressure requirement | 7 Kg/cm² | |

Hydraulic required | 70 Kg/cm² | |

Machine wt. | 136,400 lbs | 62,000 Kg |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.