OD-1524-2X

| OD | 15 in. |

|---|---|

| Length | 24 in. |

| HP | 7.5 hp |

| Wheel | 20 x 2 x 6 in. |

| OD | 15 in. |

|---|---|

| Length | 24 in. |

| HP | 7.5 hp |

| Wheel | 20 x 2 x 6 in. |

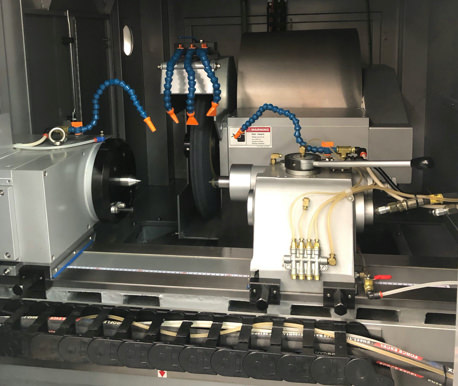

The 2-axis CNC cylindrical grinder allows versatile functions for OD grinding. Besides grinding outside diameter, shoulder and faces in one set up, it can also address complex form grindings such as tapers and radii using form dressed wheels or profiling.

| Capacity | Inch | Metric |

|---|---|---|

| Swing over Table | 15 in. | 381 mm |

| Distance Between Centers | 23.6 in. | 600 mm |

| Max Grinding Diameter | 14.2 in. | 360.68 mm |

| Max Load Between Centers | 330 lbs. | 163 kg |

| Wheelhead | OD-1524-2X | OD-1524-2X |

| Infeed Range | 9 in. | 228.6 mm |

| Minimum Increment Feed | 0.0001 in. dia. | 0.00254 mm |

| Max Increment Speed | 236 in. dia. | 5994 mm) |

| Swivel Angle | 90 degrees | 90 degrees |

| Grinding Wheel | Inch | Metric |

|---|---|---|

| OD X Width x ID | 20 x 2 x 6 in. | 508 x 50.8 x 152.4 mm |

| Optional Width | 4 in. | 101.6 mm |

| Wheel Speed | 1390 rpm | 1390 rpm |

| Workhead | Inch | Metric |

|---|---|---|

| Spindle Type | Fixed & Rotary | Fixed & Rotary |

| Spindle Speed (variable) | 30-350 rpm | 30-350 rpm |

| Diameter of Through Hole | 0.9 in. | 22.86 mm |

| Taper of Center | MT #4 (option 5) | MT #4 (option 5) |

| Table | Inch | Metric |

|---|---|---|

| Rapid Feed | 393 ipm | 9982 mm/min |

| Swivel Angle CCW | 9 degrees | 9 degrees |

| Min incremental feed | 0.0001 in. | 0.00254 mm |

| Tailstock | Inch | Metric |

|---|---|---|

| Spindle Stroke | 1 in. | 25.4 mm |

| Center Taper | MT #4 (option 5) | MT #4 (option 5) |

| Motors | Inch | Metric |

|---|---|---|

| Wheel Drive | 7.5 HP, 10HP | 5.59 Kw, 7.45 Kw |

| Workhead Drive | 2 HP | 1.49 Kw |

| Hydraulic Pump Drive | 2 HP | 1.49 Kw |

| Coolant Pump | 0.25 HP | 0.18 Kw |

| Lub Pump | 0.25 HP | 0.18 Kw |

| X/Y axis motor | 1.6 HP | 1.19 Kw |

| Tank Capacity | Inch | Metric |

|---|---|---|

| Coolant Tank | 20 gallons | 75.70 L |

| Hydraulic Tank | 15 gallons | 56.78 L |

| Measurements | Inch | Metric |

|---|---|---|

| Width x Depth | 15.41 x 7.5 ft. | 4.69 x 2.28 M |

| Height | 7.41 ft. | 2.25 M |

| Approx. Weight (Net) | 11,440 lbs. | 5189 kg |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.