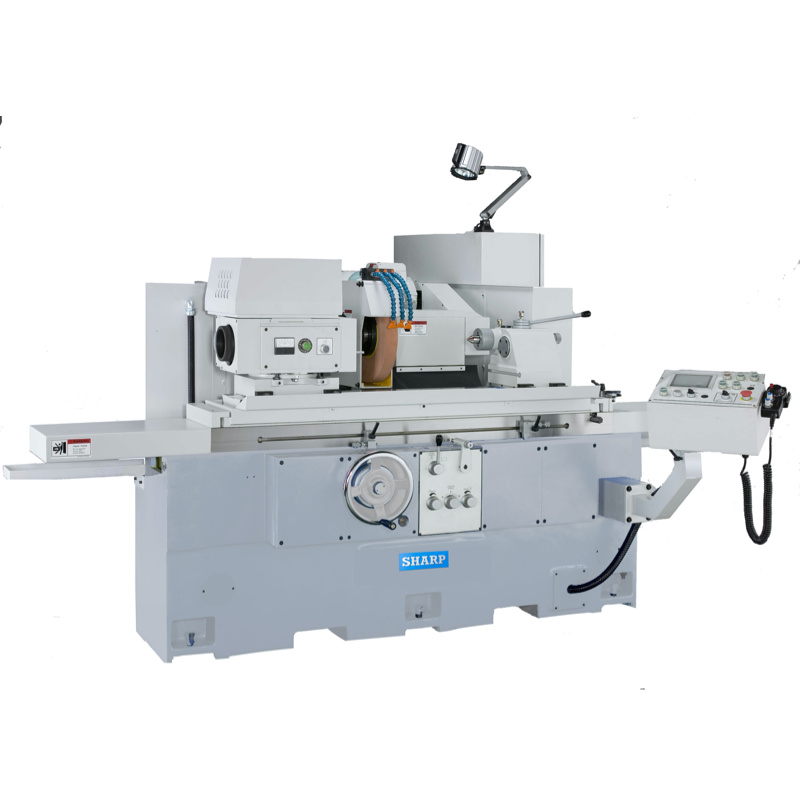

NC – OD-1020SE

| OD | 10 in. |

|---|---|

| Length | 20 in. |

| HP | 5 hp |

| OD | 10 in. |

|---|---|

| Length | 20 in. |

| HP | 5 hp |

In this model of cylindrical grinder, the wheel head infeed is driven by AC digital servo motor which controls the precise distance the wheel head moves digitally. This results in more precise repetitive OD grinding and ease of operation.

| Capacity | Inch | Metric |

|---|---|---|

| Distance Between Centers | 19.7 in. | 500.38 mm |

| Swing Over Table | 10.2 in. | 259.08 mm |

| Max Grinding Diameter | 9.9 in. | 251.46 mm |

| Max Load Between Centers | 176 lbs. | 79.83 Kg |

| Grinding Wheel | Inch | Metric |

|---|---|---|

| Wheel Dia. (Dia.x Width x Bore) | 16 x 2 x 5 in. | 406.4 x 50.8 x 127 mm |

| Wheel Speed | 1,800 rpm | 1,800 rpm |

| Wheelhead | Inch | Metric |

|---|---|---|

| Swiveling Angle (R&L) | +/- 30 degrees | +/- 30 degrees |

| Infeed Travel | 5.3 in. | 134.62 mm |

| Handfeed Travel | 3.5 in. | 88.9 mm |

| Top Slide Travel | 7 in. | 177.8 mm |

| Automatic Rapid Travel | 1.75 in. | 44.45 mm |

| Auto Increment Infeed (SE only) | 0.0001-0.1 in. | 0.00254-2.54 mm |

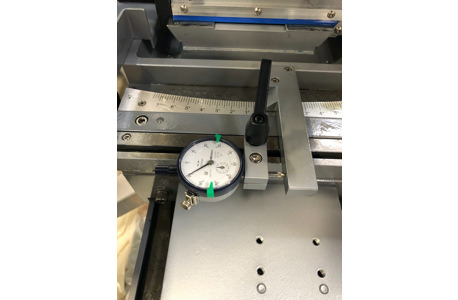

| Handwheel per Graduation (dia.) | 0.0002 in. | 0.00508 mm |

| Handwheel per Revolution (dia.) | 0.1 in. | 2.54 mm |

| Workhead | Inch | Metric |

|---|---|---|

| Swiveling Angle (R&L) | +/- 45 degrees | +/- 45 degrees |

| Center Taper | MT 3 | MT 3 |

| Spindle Speed (variable) | 30-350 rpm | 30-350 rpm |

| Tailstock | Inch | Metric |

|---|---|---|

| Quill Travel | 1 in. | 25.4 mm |

| Center Taper | MT # 3 | MT # 3 |

| Table | Inch | Metric |

|---|---|---|

| Swiveling Angle (R&L) | +/- 8 degrees | +/- 8 degrees |

| Traverse Speed | 1.2-275 ipm | 30.48-6,985 mm |

| Handwheel per Revolution | 0.39 in. | 9.90 mm |

| ID Grinder(opt) | Inch | Metric |

|---|---|---|

| Grinding Bore Range | 1.18-3.94 in. | 29.9-100.07 mm |

| Max Grinding Length | 4.3 or 2.2 in. | 109.22 or 55.88 mm |

| Max Chucking Length | 12.4 in. | 314.96 mm |

| Max Chucking Diameter | 6 in. | 152.4 mm |

| Motor | Inch | Metric |

|---|---|---|

| Wheel Spindle Motor | 5 HP | 3.72 Kw |

| Workhead Motor | 0.5 HP | 0.37 Kw |

| Hydraulic Pump | 2 HP | 1.49 Kw |

| Internal Grindiing Motor | 0.5 HP |

| General | Inch | Metric |

|---|---|---|

| Gross Weight | 6,160 lbs. | 2,794.12 Kg |

| Packing Dimensions | 7.5 x 7.5 x 6.3 ft. | 2.28 x 2.28 x 1.92 M |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.