KMA-3H

| Long. x Cross Travel | 59 (79 Opt) x 23.6 in. |

|---|---|

| Vert. Head Travel | 27.5 in. |

| Horiz. Head Travel | 25.5 in. (up, down) |

| Vert., Horiz. Taper, HP | #50, #50, 17.5 HP, 7.5 HP |

| Long. x Cross Travel | 59 (79 Opt) x 23.6 in. |

|---|---|

| Vert. Head Travel | 27.5 in. |

| Horiz. Head Travel | 25.5 in. (up, down) |

| Vert., Horiz. Taper, HP | #50, #50, 17.5 HP, 7.5 HP |

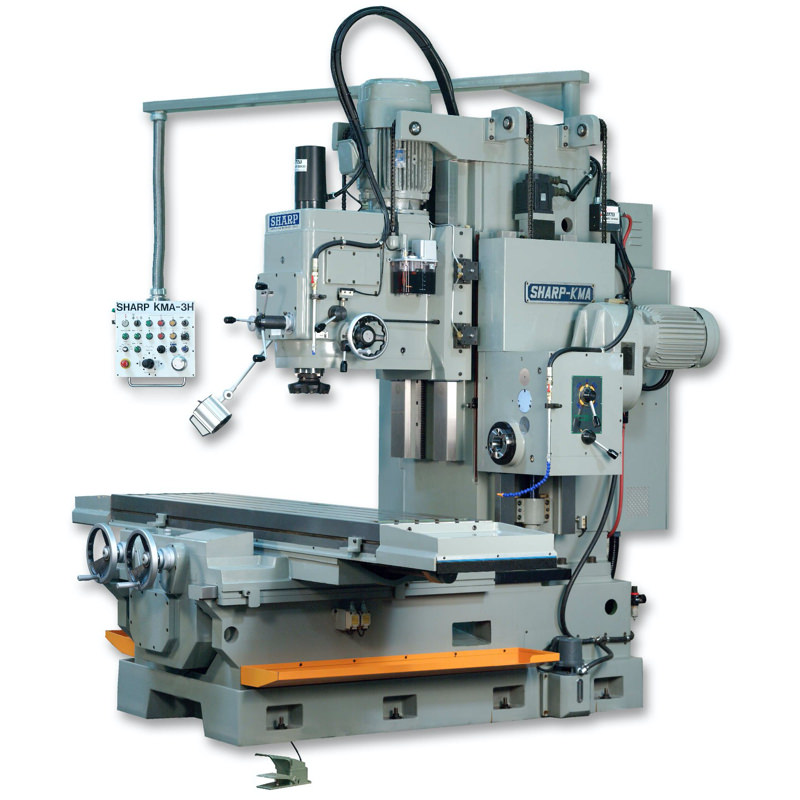

This model has both vertical and horizontal heads. Bed type vertical milling machines are ideal for milling large work piece or heavy cutting on hard metals. The quill is fixed so it can withstand strong lateral forces. For this model, the entire vertical head moves up to 28” that enables deep drilling and boring operations. The large spindle with #50 taper can remove large amount of metals in one pass. The horizontal head with 7.5 HP motor and #50 taper spindle driven by AC servo motor on ballscrew performs horizontal milling operations with high accuracy. This arrangement allows the performing of different type of milling operations on one set up, thus maintain accuracy and increase productivity.

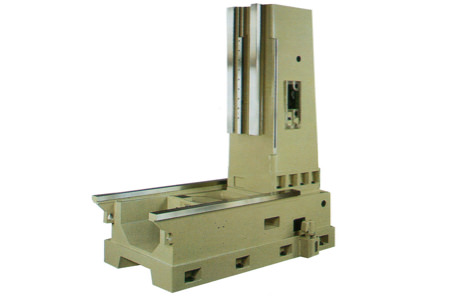

High quality castings are used on base, column, saddle and table. They are stressed relieved to avoid any distortion. All sliding surfaces are hand scraped to ensure full bearing support. All reference surfaces and T slots are precision ground to exact tolerances

The vertical column of a bed mill usually received most pressure during heavy duty milling operations. Honeycombed pattern ribbings enhance rigidity of the casting.

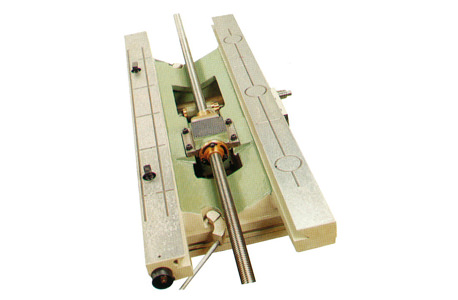

Backlash on the screw increases after long term usages. The backlash eliminator can correct the situation by adjusting the double nuts instead of the old method of squeezing a split nut.

Despite the heavy duty vertical spindle head, it is easy to move the head up and down manually using the tri-lever handle for positioning or close milling jobs.

The operating panel has additional buttons and switches for the horizontal head with horizontal spindle start, stop and jog. It has manual and auto horizontal head feed, rapid feed with feed override. It also has an electronic handwheel (MPG) for controlling the up and down feed of the head with ease.

The horizontal milling head with a fixed quill travels along the side of the column driven by AC servo motor on precision ball screw. It is equipped with NST#50 spindle taper, runs on 7.5 HP spindle motor. The head has 12 spindle speeds from 40-1,450 rpm.

| Capacity | Inch | Metric |

|---|---|---|

| Table Size | 19.68 x 86.62 in. | 499.87 x 2200.14 mm |

| T-slots (No.x Width x Pitch) | 5 x 0.75 x 3.56 in. | 5 x 19.05 x 90.42 mm |

| Table Travel : X Longitudinal | 59 in. (79 in. Opt) | 1498 mm (2,006 mm Opt) |

| Table Travel : Y Cross | 23.6 in. | 599 mm |

| Vertical Head Travel | 27.5 in. | 698 mm |

| Horizontal Head Travel | 25.5 in. (up, down) | 647 mm |

| Vertical, Horizontal Taper, HP | #50, #50, 20 HP, 7.5 HP | |

| Spindle Center to Column | 21.62 in. | 549.14 mm |

| Spindle Nose to Table | 4-31.5 in./min | 101.6-800.1 mm/min |

| Distance Between Vertical and Horizontal Spindle | 21.5 in. | 546 mm |

| Table Feeds, Rapids | Inch | Metric |

|---|---|---|

| Longitudinal Feeds (Variable) | 1.12 - 39.37 ipm | 26 -1000 mm/min |

| Longitudinal Rapids | 129-7/8 ipm | 3300 mm/min |

| Cross Feeds (Variable) | 1.12 - 39.37 ipm | 26 -1000 mm/min |

| Cross Rapids | 129-7/8 ipm | 3300 mm/min |

| Vertical Head | Inch | Metric |

|---|---|---|

| Spindle Nose Taper | NST #50 | |

| Spindle Speeds (12) | 45 - 1500 rpm | |

| Vertical head Travel | 25-9/16 in. | 700 mm |

| Vertical Head Feeds | 0.002-0.008 in/rev | 0.05-0.2 mm/rev |

| Horizontal Head | Inch | Metric |

|---|---|---|

| Spindle Nose Taper | NST #50 | |

| Spindle Speed (12) | 40 - 1450 rpm | |

| Horizontal Head Travels | 25.5 in. (up, down) | 647 mm |

| Vertical Rapids | 150 ipm | 3800 mm/min |

| Motors | Inch | Metric |

|---|---|---|

| Vertical Spindle | 20 HP | 14.91 Kw |

| Horizontal Spindle | 7.5 HP | 5.59 Kw |

| Table Feed and Rapid | 4.7 HP | 3.5 Kw |

| Vertical Rapid | 1.14 HP | 0.85 Kw |

| Coolant System | 0.125 HP | 0.093 Kw |

| General | Inch | Metric |

|---|---|---|

| Floor Area (W x D x H) | 14.58 x 8.33 x 9.41 ft. | 4.44 x 2.53 x 2.86 M |

| Approximate Weight | 19,140 lbs. | 8,700 Kg |

| Power Consumption (220V) | 60 amps | |

| Power Consumption (440V) | 30 amps |

All specifications subject to change without notice. Please call to verify.

| Long. Travel | 79 in. (99 in. opt) |

|---|---|

| Cross Travel | 31.5 in. |

| Vert. Head Travel | 27-9/16 in. |

| Taper, HP | #50, #50, 17.5 HP, 7.5 HP |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.