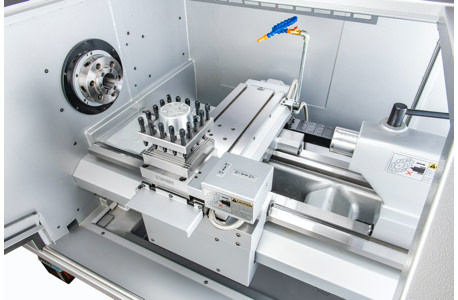

1840TC-F

| Swing | 18 in. |

|---|---|

| Center Distance | 40 in. |

| Bore, HP | 2.3 in., D1-6, 10 hp |

| Swing | 18 in. |

|---|---|

| Center Distance | 40 in. |

| Bore, HP | 2.3 in., D1-6, 10 hp |

This is a user friendly CNC lathe with full CNC functions and manual operation functions. It has programmable spindle speed, and 4- way tool post positioning. The Electronic handwheel (MPG) can be used for manual operation.

The Fanuc OiTF all digital control and drive package provides exceptional value and reliability. The control features a clear 8.4” LCD screen that pivots out of easy operator viewing. It can catalog 400 part-program numbers and features an internal 2 GB solid state Data Server with 512 K RAM memory reserved for part programs. It features an embedded high speed Ethernet capability and AICC II and includes DB-25, RS-232 serial interface, RJ-45 Ethernet interface USB, and PC MCIA CF memory card connections for program transfer. Manual Guide-i conversational programming provides fast & efficient intuitive menu driven shop floor programming and includes a Thread Repair Cycle. An MPG handwheel is also provided.

Selected functions:

| Capacity | Inch | Metric |

|---|---|---|

| Swing Over Bed | 18 in. | 457.2 mm |

| Swing Over Cross Slide | 9 in. | 228.6 mm |

| Distance Between Centers | 39.4 in. | 1,000.76 mm |

| Headstock | Inch | Metric |

|---|---|---|

| Spindle Speed | 43-2500 rpm | |

| Spindle Nose | D1-6 camlock | |

| Spindle Bore | 2.37 in. | 60.19 mm |

| Carriage | Inch | Metric |

|---|---|---|

| Cross Slide Travel | 10.63 in. | 270 mm |

| Bed | Inch | Metric |

|---|---|---|

| Bed Length | 82.5 in. | 2,095.5 mm |

| Bed Width | 14.5 in. | 368.3 mm |

| Tailstock | Inch | Metric |

|---|---|---|

| Quill Diameter | 2.93 in. | 74.42 mm |

| Quill Travel | 6.31 in. | 160.27 mm |

| Quill Center Taper | MT #5 |

| General | Inch | Metric |

|---|---|---|

| Spindle Motor | Fanuc 10 HP | 7.45 Kw |

| Approximate Weight | 5,732 lbs. | 2,599.9 Kg |

| Dimensions | 8.33 x 4.58 x 6.08 ft. | 2.53 x 1.39 x 1.85 M |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.