1118H

| Swing x Center Dist | 11 x 18 in. |

|---|---|

| Spindle Speed | 4,000 rpm |

| Spindle Bore, Motor | 1.06 in., 5 hp |

| Spindle Accuracy TIR | 0.000050 in. |

| Swing x Center Dist | 11 x 18 in. |

|---|---|

| Spindle Speed | 4,000 rpm |

| Spindle Bore, Motor | 1.06 in., 5 hp |

| Spindle Accuracy TIR | 0.000050 in. |

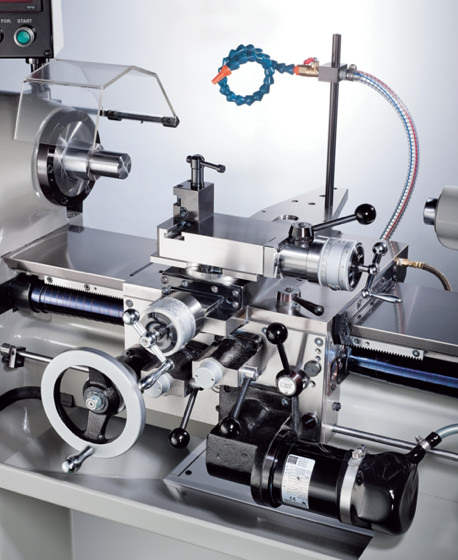

This toolroom lathe is ideal for small parts especially for those that requires threading. It offers very high precision (0.000050” TIR) and fast turn around time for machining tiny parts.

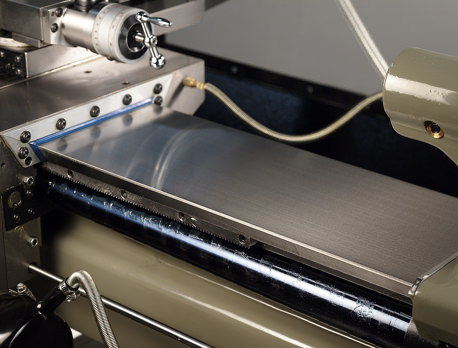

Flat piece bed way that cover entire bed width gives full bearing surface for the carriage travel. Bedway is made of alloy tool steel for minimum wear after long years of use. This ensures long lasting accuracy along the Z axis travel.

Quick action compound slide facilitate the threading process.

| Spindle Capacity | Inch | Metric |

|---|---|---|

| With Jaw Chucks | 6 in. | 150 mm |

| With Expanding Collets | 3 in. | 76 mm |

| With Round 5C Collets | 1-1/16 in. | 27 mm |

| With Step Chucks | 1-1/16 - 6 in. | 27 - 152 mm |

| General Capacity | Inch | Metric |

|---|---|---|

| Swing Over Bed | 11 in. | 280 mm |

| Swing Over Cross Slide | 6 in. | 152 mm |

| Distance Between Centers | 18 in. | 457 mm |

| Headstock | Inch | Metric |

|---|---|---|

| Spindle Speed | 50 - 4000 rpm | 50 - 4000 rpm |

| No. of Spindle Speeds | Variable (high/low) | |

| Spindle Nose Diameter | 2.19 in. | 55.5 mm |

| Spindle Bore | 1-1/4 in. | 31.75 mm |

| Spindle Nose ID/OD | 5C 10°/4° taper | 5C 10°/4° taper |

Threads and Feeds | Inch | Metric |

|---|---|---|

Threads / Number | 11 - 108 tpi / 36 | 0.275 - 2.7 / 36 |

Longitudinal Feeds | 0.31 - 7 ipr | 8 - 178 mm/r |

| Cross Feeds | 0.18 - 4 ipr | 5 - 102 mm/r |

| Leadscrew Pitch, Diameter | 8 tpi, 1 in. | 8 tpi, 25.4 mm |

| Carriage | Inch | Metric |

|---|---|---|

| Cross Slide Travel | 6 in. | 152 mm |

| Compound Slide Travel | 3 in. | 76 mm |

| Quick Action Compound Travel | 0.1 in. | 2.5 mm |

| Tailstock | Inch | Metric |

|---|---|---|

| Quill Diameter | 1.35 in. | 34.5 mm |

| Quill Travel | 3.75 in. | 95 mm |

| Quill Center Taper | MT #2 | MT #2 |

| General | Inch | Metric |

|---|---|---|

| Spindle Motor | 5 HP | 3.7 KW |

| Voltage | 220V, 440V | |

| Phase | 3 Ph (no 1 Ph) | |

| Coolant Pump Motor | 0.167 HP | 0.124 Kw |

| Carriage Feed Motor (DC) | ½ HP, 220V | 0.37 Kw |

| Approximate Weight | 1804 lbs | 820 Kg |

| Dimensions | 6.07 x 2.46 x 5.58 ft. | 1.85 x 0.75 x 1.70 M |

All specifications subject to change without notice. Please call to verify.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.