OD-816

| OD | 8 in. |

|---|---|

| Length | 16 in. |

| HP | 3 hp |

| OD | 8 in. |

|---|---|

| Length | 16 in. |

| HP | 3 hp |

The spindle runs on precision bearings, assuring maximum spindle stability. It guarantees outstanding grinding accuracy for external dia., internal dia., (optional) & end face.

The spindle head swivels +90° ~ 30°. The spindle head on the OD-816 series machines provides variable speed changed by frequency inverter.

The grinding wheel spindle is precision machined from high quality alloy steel, normalized, tempered, carburized and sub-zero treated, precision ground and mirror-effect treated.

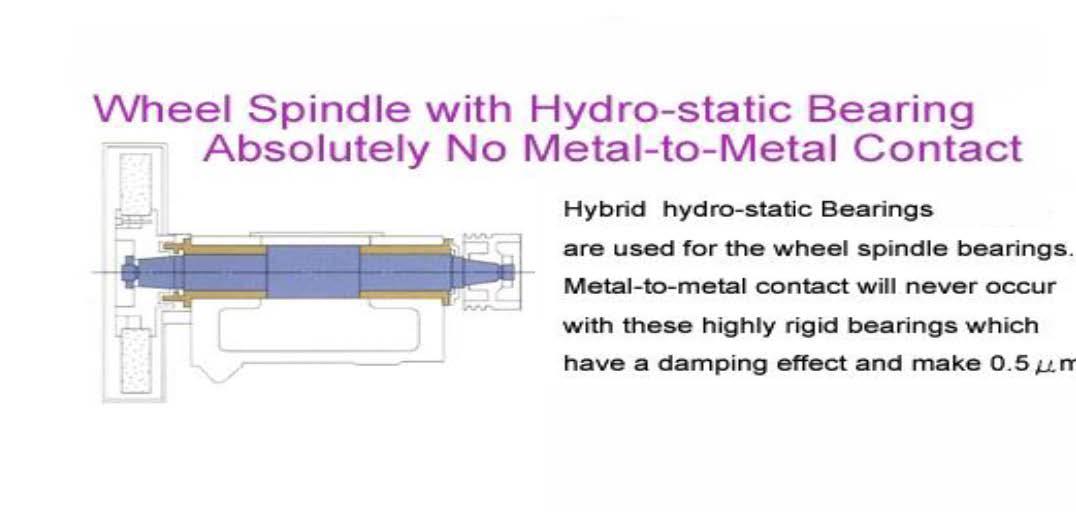

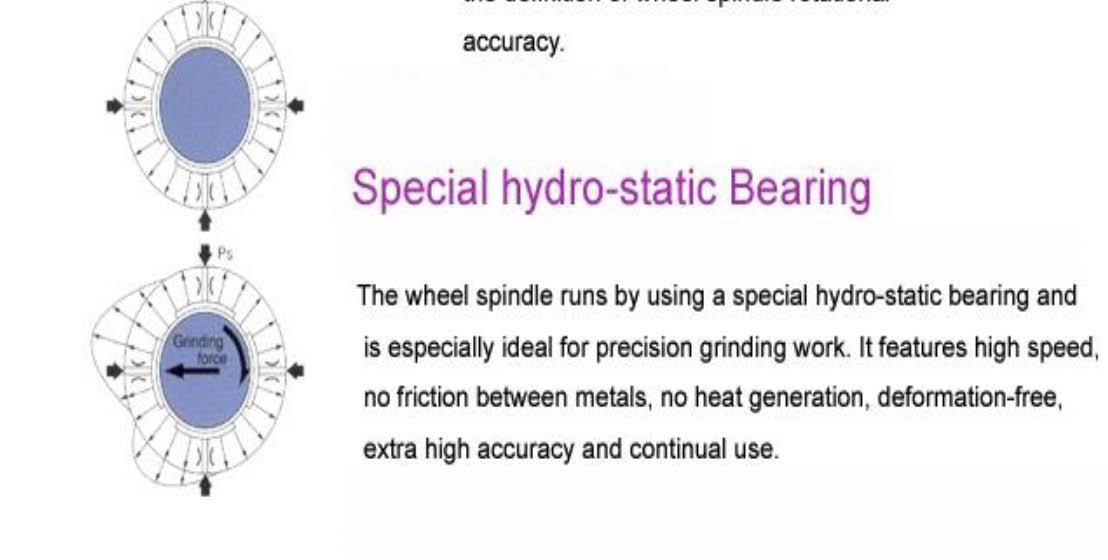

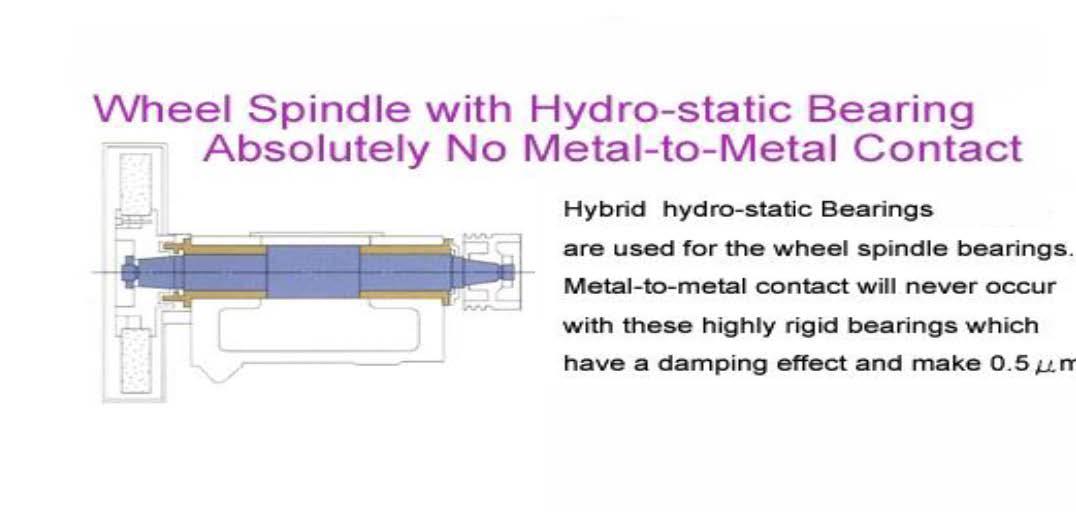

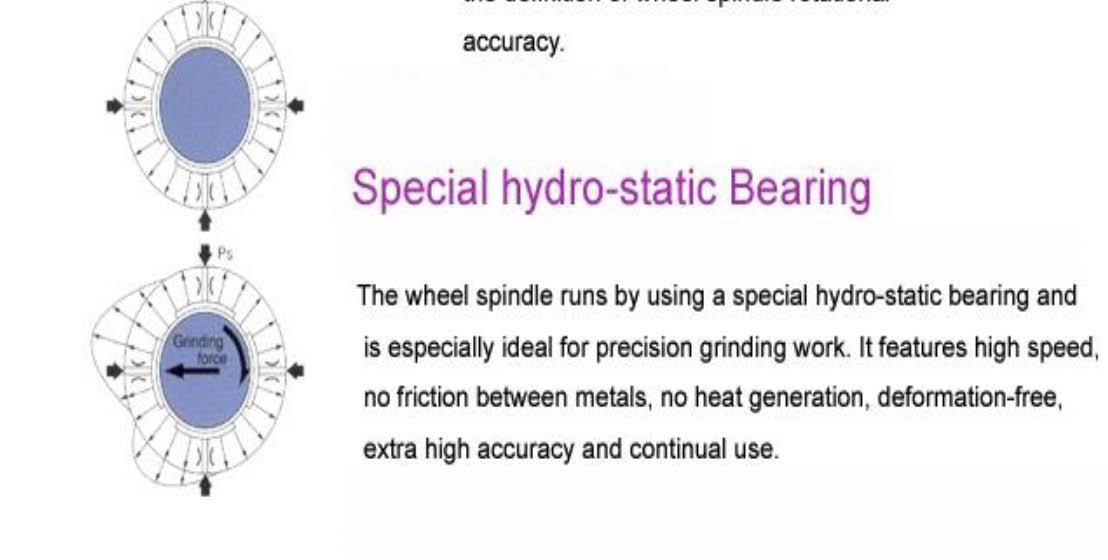

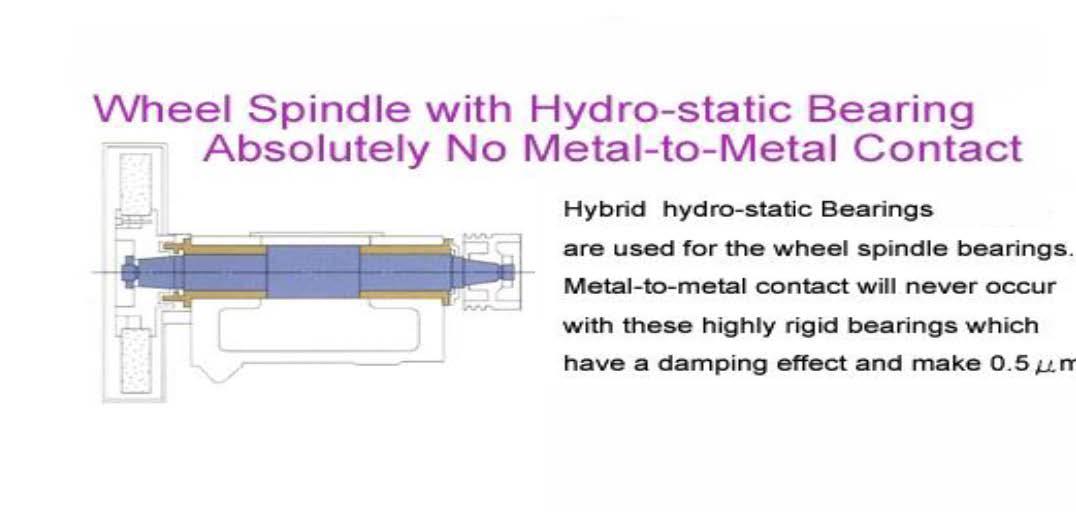

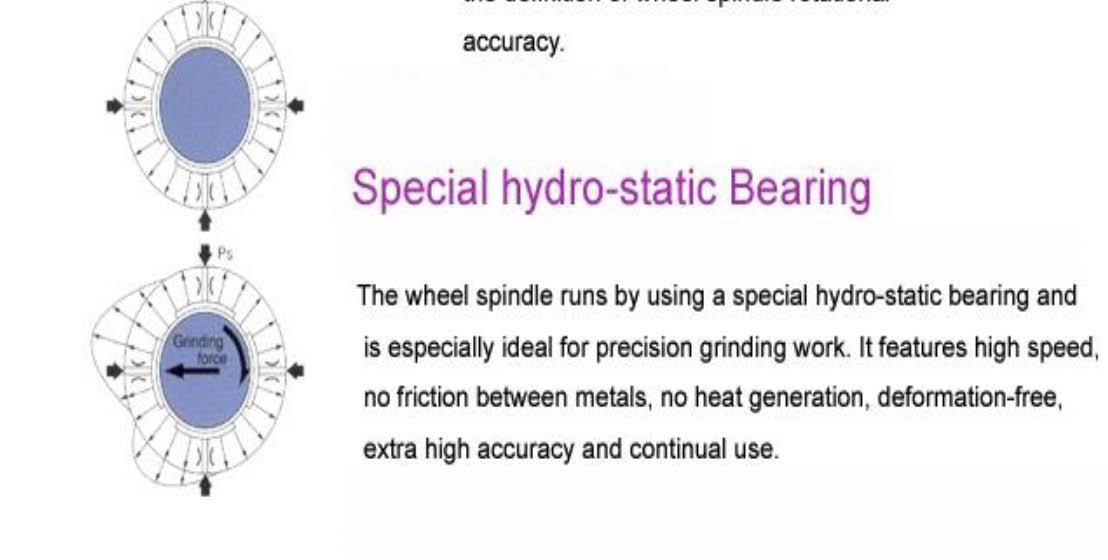

The wheel spindle runs by using a special hydrostatic bearing and is especially ideal for precision grinding work. It features high speed, no friction between metals, no heat generation, deformation-free, extra high accuracy and continual use. Hybrid hydrostatic bearings are used for the wheel spindle bearings. Metal-to-metal contact will never occur with these highly rigid

The spindle runs on precision bearings, assuring maximum spindle stability. It guarantees outstanding grinding accuracy for external dia., internal dia., (optional) & end face.

The spindle head swivels +90° ~ 30°. The spindle head on the OD-816 series machines provides variable speed changed by frequency inverter.

The grinding wheel spindle is precision machined from high quality alloy steel, normalized, tempered, carburized and sub-zero treated, precision ground and mirror-effect treated.

The wheel spindle runs by using a special hydrostatic bearing and is especially ideal for precision grinding work. It features high speed, no friction between metals, no heat generation, deformation-free, extra high accuracy and continual use. Hybrid hydrostatic bearings are used for the wheel spindle bearings. Metal-to-metal contact will never occur with these highly rigid

| Capacity | Inch | Metric |

|---|---|---|

| Distance Between Centers | 15.7 in. | 400 mm |

| Swing Over Table | 7.87 in. | 200 mm |

| Max Grinding Diameter | 7.09 in. | 180 mm |

| Max Load Between Centers | 133 lbs. | 60 Kg |

Grinding Wheel | Inch | Metric |

|---|---|---|

OD x Width x ID | 14 x 1.5 x 5 in. | 355 x 38 x 127 mm |

Min. Input Increment | 0.001mm | 0.001mm |

Linear Velocity | 45m/s | 45m/s |

Internal Grinding | Manual Elevation | |

Spindle Bearing | Special Completed Hydrostatic Bearing |

| Wheelhead | Inch | Metric |

|---|---|---|

| Swiveling Angle (R&L) | fixed | fixed |

| Infeed Travel | 6.3 in. | 160.02 mm |

| Handfeed Travel | 6.3 in. | 160.02 mm |

| Top Slide Travel | 7 in. | 177.8 mm |

| Automatic Rapid Travel | 1.75 in. | 44.45 mm |

| Auto Increment Infeed (SE only) | 0.001 – 0.1 in. | 0.0254-2.54 mm |

| Handwheel per Graduation (dia.) | 0.0002 in. | 0.00508 mm |

| Handwheel per Revolution (dia.) | 0.1 in. | 2.54 mm |

Workhead | Inch | Metric |

|---|---|---|

| Swiveling Angle (R&L) | 30° ~ + 90° | 30° ~ + 90° |

| Center Taper | MT 4 | MT 4 |

| Spindle Speed (Variable) | 10-300 rpm (Variable) | 10-300 rpm (Variable) |

Max. load of Spindle (tool holder included) | 15 kgs (Max.Length: 100mm) | 15 kgs (Max.Length: 100mm) |

| Tailstock | Inch | Metric |

|---|---|---|

Tailstock Stroke | 1 in. | 25 mm |

| Center Taper | MT # 3 | MT # 3 |

Table | Inch | Metric |

|---|---|---|

| Swiveling Angle (R&L) | 0° ~ 10° | 0° ~ 10° |

Rapid Feed rate | 10 m/min | 10 m/min |

Min. Input Increment | 0.001mm | 0.001mm |

Table Lubrication | Hydraulic static Slideway Lubrication |

| ID Grinder (opt) | Inch | Metric |

|---|---|---|

| Spindle Speed | 14,000 or 25,000 rpm | 14,000 or 25,000 rpm |

| Grinding Bore Range | 0.95-2.75 in. | 24.13-69.85 mm |

| Max Grinding Length | 2.75 in. | 69.85 mm |

| Max Chucking Length | 10.8 in. | 274.32 mm |

| Max Chucking Diameter | 4 in. | 101.6 mm |

Motor | Inch | Metric |

|---|---|---|

| Wheel Spindle Motor | 3 HP | 2.23 Kw |

| Workhead Motor | 0.5 HP | 0.37 Kw |

| Internal Grinding Motor | 0.25 HP | 0.18 Kw |

Coolant Pump | 0.25 HP | 0.18 Kw |

Wheel Spindle Lubrication Pump | 0.25 HP | 0.18 Kw |

Hydraulic Pump | 0.5 HP | 0.37 Kw |

Tank Capacities | Inch | Metric |

|---|---|---|

Wheel Spindle Bearing Lubricate | 7 L | 7 L |

Lubrication Oil Tank | 46 L | 46 L |

General | Inch | Metric |

|---|---|---|

| Net Weight | 4,070 lbs. | 2000 Kgs. |

All specifications subject to change without notice. Please call to verify.

Optional Accessories

The spindle runs on precision bearings, assuring maximum spindle stability. It guarantees outstanding grinding accuracy for external dia., internal dia., (optional) & end face.

The spindle head swivels +90° ~ 30°. The spindle head on the OD-816 series machines provides variable speed changed by frequency inverter.

The grinding wheel spindle is precision machined from high quality alloy steel, normalized, tempered, carburized and sub-zero treated, precision ground and mirror-effect treated.

The wheel spindle runs by using a special hydrostatic bearing and is especially ideal for precision grinding work. It features high speed, no friction between metals, no heat generation, deformation-free, extra high accuracy and continual use. Hybrid hydrostatic bearings are used for the wheel spindle bearings. Metal-to-metal contact will never occur with these highly rigid

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.