SVX-500-F

| Travel | 24 x 32 x 20 in. |

|---|---|

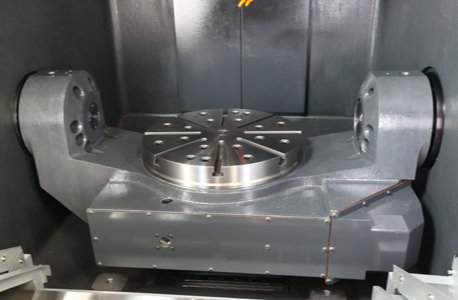

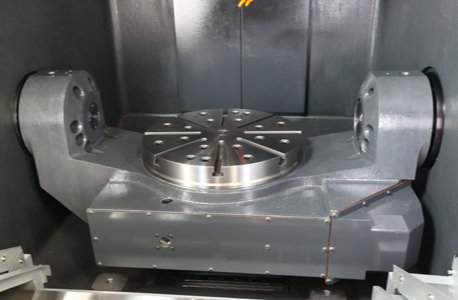

| Trunnion Table | 20 in. |

| A Axis Travel | -110 – 20° |

| C Axis Rotates | 360° |

| Travel | 24 x 32 x 20 in. |

|---|---|

| Trunnion Table | 20 in. |

| A Axis Travel | -110 – 20° |

| C Axis Rotates | 360° |

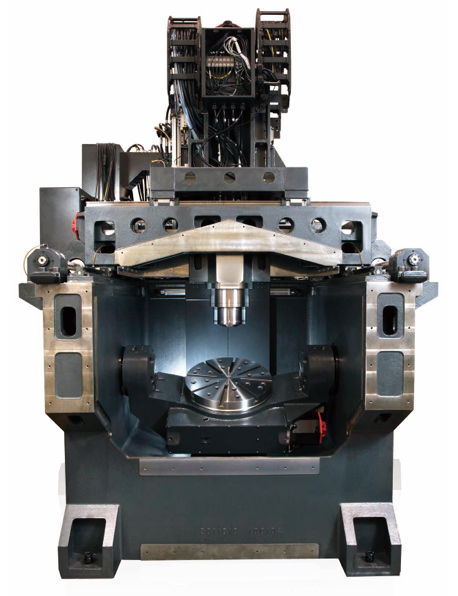

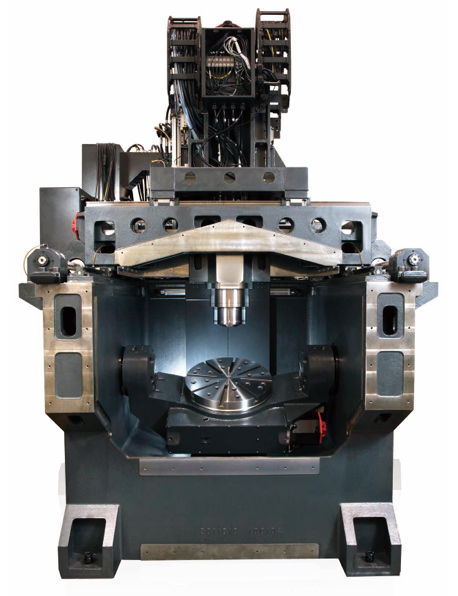

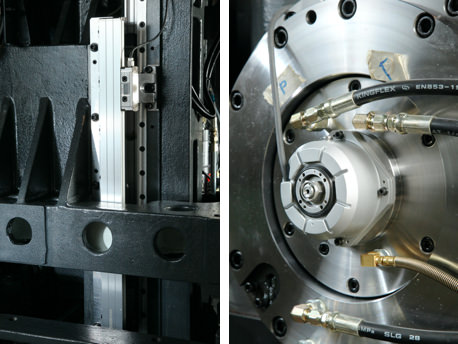

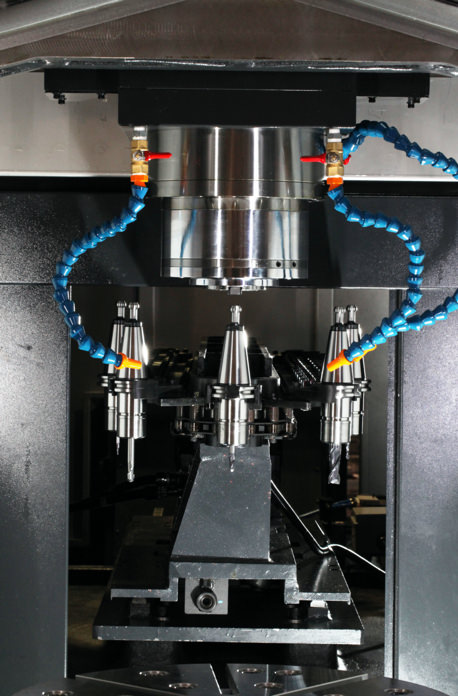

The Sharp SVX-500 vertical machining center is engineered to have unrivaled quality and outperform all other machines in its category. Sharp’s SVX-500 allows true 5-sided and 5-axis simultaneous machining. Unlike the 3-axis that requires a separate setup for cutting different sides of a part, the 5-axis machine requires the part to be set only once and rotated into a series of positions to machine each side without the need to reset the part. All major castings of the SVX-500 are analyzed using the Finite Element Method (FEM) to locate areas of stress and strain, multiple loading conditions from thermal, gravity, centrifugal and enforced displacement. Ribs locations are properly defined to maintain rigidity throughout the entire machine. The 5-axis is constructed using the box-in-box design to assure accuracy and rigidity under different cutting conditions.

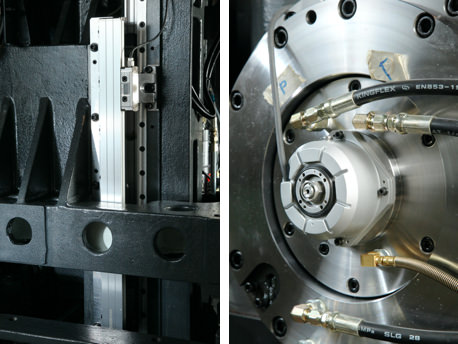

Packing a motor and machining spindle in one unit eliminate couplings, belts, and gearboxes. It also lets them cut back on spindle inertia and increase acceleration and deceleration times. The lack of drive-traverse forces makes the spindles accurate, thanks to smooth, precise spindle motion even at low speeds. The units is compact, lightweight, and have high power densities.

Ceramic bearings are more corrosion-resistant, harder, and last longer in everyday use. Light lubrication is needed, so they roll much quicker with less drag than standard steel bearings. Ceramic deals with heat better, so less friction is a bonus.

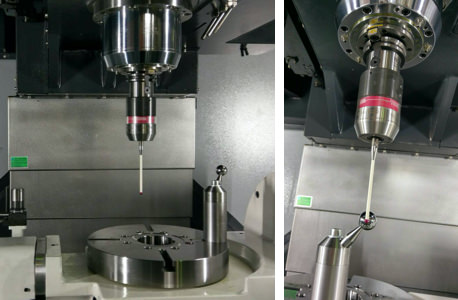

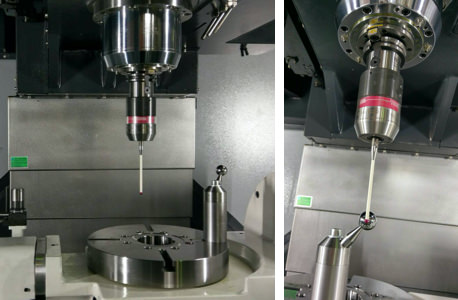

BLUM Z-nano Tool Setter for tool breakage detection and tool length measurement

BLUM T-60 Touch Probe to identify and set-up parts, measure features in‑cycle for adaptive machining, monitor workpiece surface condition and verify finished component dimensions.

Above two devices are standard on the machine.

| Work Capacity | Inch | Metric |

|---|---|---|

| X axis travel | 23.6 in. | 600 mm |

| Y axis travel | 31.9 in. | 810 mm |

| Z axis travel | 19.7 in. | 500 mm |

| A axis travel (tilting) | -110 to +20' | -110 to +20' |

| C axes travel (rotation) | 360° | 360° |

| Spindle nose to table (A= 0°) | 1.9-21.7 in. | 50-550 mm |

| Table Area | Inch | Metric |

|---|---|---|

| Max Work Piece Weight | 770 lbs. | 350 kg |

| T-Slot (No. x Width x degree) | 0.7 in. x 45 degrees | 18 mm x 45 degrees |

| Round Table Diameter | 19.6 in. | 500 mm |

| Spindle | Inch | Metric |

|---|---|---|

| Spindle taper | ISO 7/24 40 BBT Dual Contact | ISO 7/24 40 BBT Dual Contact |

| Spindle speed | 15,000 ceramic bearing | 15,000 ceramic bearing |

| Spindle motor: cont./30 min | 20/25 HP | 15/18.5 Kw |

| Spindle torque: 15 minute rating | 118 Nm at 1500 rpm / 42 Nm at 5000 rpm | 118 Nm at 1500 rpm / 42 Nm at 5000 rpm |

| Transmission | Built in | Built in |

| Automatic Tool Changer | Inch | Metric |

|---|---|---|

| ATC type | From behind and under spindle | From behind and under spindle |

| Tool capacity | 30 | 30 |

| Max. tool diameter | 2.99 in. | 76 mm |

| Without adjacent tool | 4.92 in. | 125 mm |

| Max. tool length | 11.8 in. | 300 mm |

| Max. tool weight | 15.4 lbs. | 7 kg |

| Method of tool selection | Fixed | Fixed |

| Motion | Inch | Metric |

|---|---|---|

| Rapid traverse | X/Y: 2,362 ipm / Z: 1,890 ipm | X/Y: 60,000 mm/min / Z: 48,000 mm/min. |

| Cutting feed rate | 0.04-1,890 ipm | 1-48,000 mm/min |

| Feed motor (Fanuc) nm (inch) | X/Y/C: alpha 22/4000 / Z: alpha 22B/4000 / A: alpha 40B/4000 | X/Y/C: alpha 22/4000 / Z: alpha 22B/4000/ A: alpha 40B/4000 |

| Positioning accuracy | 0.00006 in. | 0.0015 mm |

| Repeatability accuracy | 0.00006 in. | 0.0015 mm |

| A axis position accuracy +/- arc sec | 6 | 6 |

| A axis repeatability accuracy +/- arc sec | 3 | 3 |

| C axis position accuracy accuarcy +/- arc sec | 5 | 5 |

| C axis repeatability accuracy accuarcy +/- arc sec | 3 | 3 |

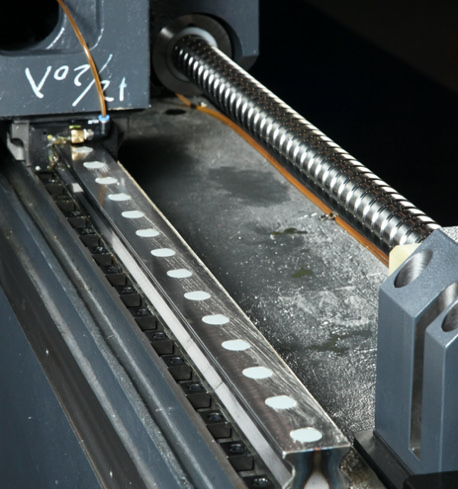

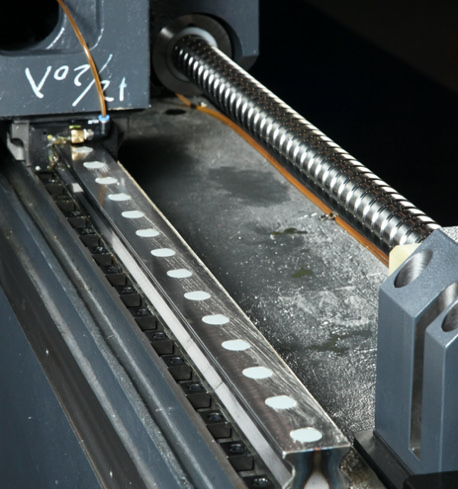

| Ballscrew diameter X/Y/Z | 1.77 in. | 45 mm |

| Coolant System | Inch | Metric |

|---|---|---|

| Coolant tank capacity | 63 gal | 240 L |

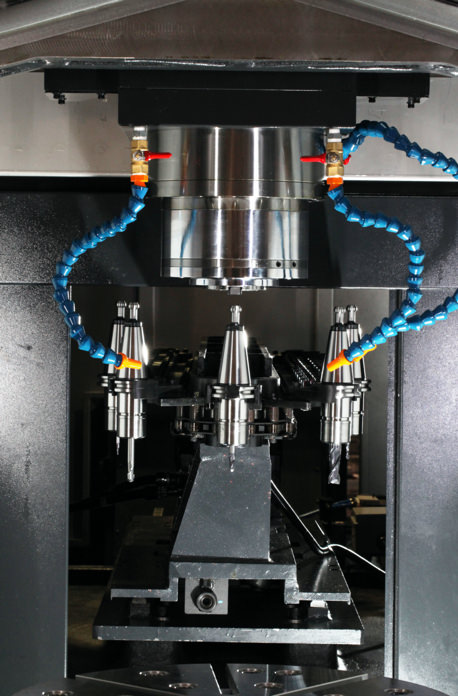

| Number of Flood Coolant Nozzles | 4 | 4 |

| Machine Size | Inch | Metric |

|---|---|---|

| Floor space (w/o chip conveyor) | W: 91.3 in. x D: 169 in. | W: 2320 mm x D: 4295 mm |

| Height | 127.1 in. | 3230 mm |

| Weight | 28,050 lbs. | 12,750 lbs. |

| Door opening | 31.5 in. | 800 mm |

| Power Requirements | Inch | Metric |

|---|---|---|

| Electrical | 220V / 60 Hz / 3 Phase / 45 KVA | 220V / 60 Hz / 3 Phase / 45 KVA |

| Air | 6 CFM at 88 psi | 6 CFM at 88 psi |

All specifications subject to change without notice. Please call to verify.

Packing a motor and machining spindle in one unit eliminate couplings, belts, and gearboxes. It also lets them cut back on spindle inertia and increase acceleration and deceleration times. The lack of drive-traverse forces makes the spindles accurate, thanks to smooth, precise spindle motion even at low speeds. The units is compact, lightweight, and have high power densities.

Ceramic bearings are more corrosion-resistant, harder, and last longer in everyday use. Light lubrication is needed, so they roll much quicker with less drag than standard steel bearings. Ceramic deals with heat better, so less friction is a bonus.

BLUM Z-nano Tool Setter for tool breakage detection and tool length measurement

BLUM T-60 Touch Probe to identify and set-up parts, measure features in‑cycle for adaptive machining, monitor workpiece surface condition and verify finished component dimensions.

Above two devices are standard on the machine.

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.